Partner-up

‘The following step in our innovation programme is to look further ahead: what will the offshore wind market be up to in the next 10 to 15 years? Without the right partners and initiatives like the Van Oord Innovation Challenge, we would not be able to prepare for the future. I cannot emphasise enough just how important cooperation is to success in my field. I’m realistic. We aren’t the only ones coming up with smart solutions – they’re being developed by other, external parties all over the world. So we have to use partnerships, challenges and other knowledge-sharing initiatives to obtain the expertise that we need for our innovation programme.’

In-house power house

‘Right now our innovation programme is focused on the short term: what can we achieve in the next five years? I work on various trials concentrating on different themes, for example noise reduction, pile-driving hammers or floating installation, and I link them to objectives. Within each theme, I collaborate with ambassadors who inspire one another and propose new techniques. We take the ambassadors’ findings and recommendations and use them as a basis for planning our investments in new innovation projects.’

It is in our nature to care

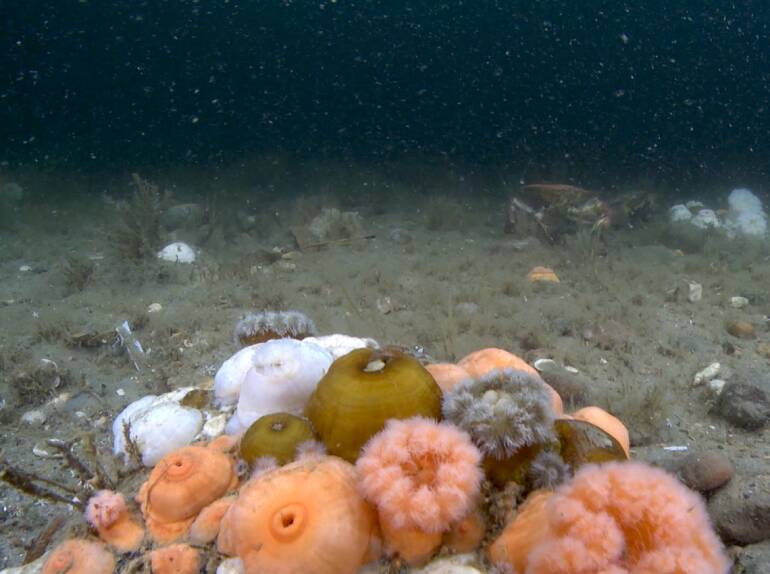

‘Van Oord has spent several years now testing how to restore or support wildlife at sea. We have been working with Dutch teaching and research institutions to develop methods for large-scale oyster cultivation and planting. For example, we’re performing laboratory tests with various oyster species, substrates and water conditions, so that besides offshore construction, we can create opportunities to improve aquatic nature and biodiversity at the same time.’

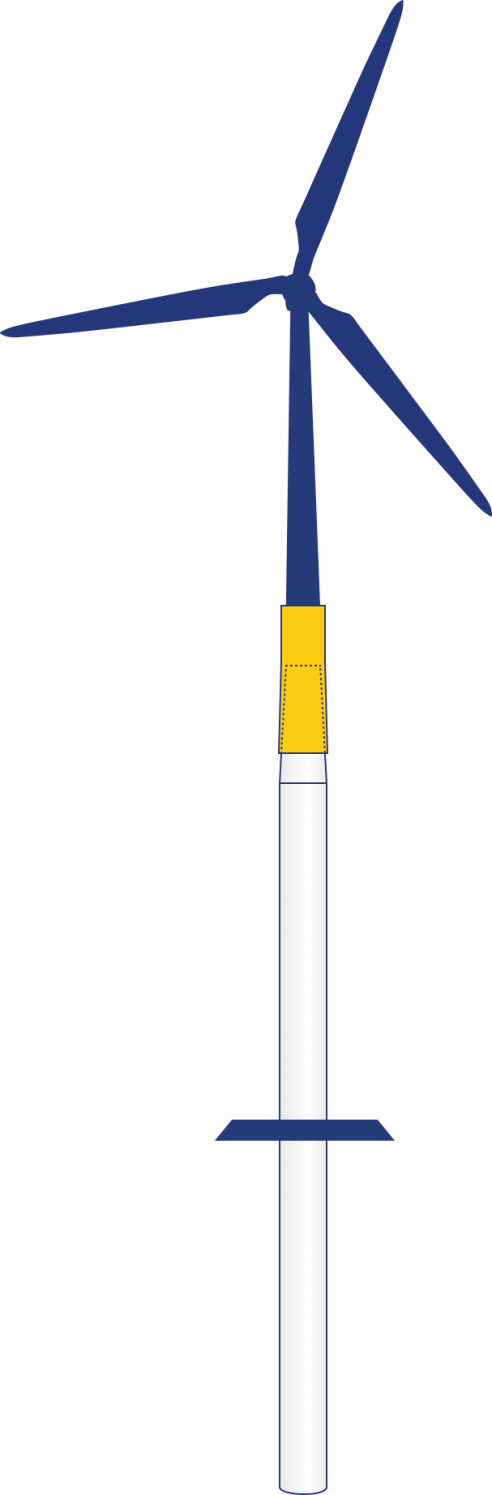

An offshore wind project is carried out in different steps: first we drive a monopile into the seabed, then we install the transition piece, then the tower, and then the gondola and the rotor blades. Each and every step takes time and is vulnerable to weather conditions. By reducing or simplifying the steps, for example with the help of the slip joint, we can achieve a considerable cost saving.’

in developing the slip joint for more than six years. After its introduction, we started off making drawings and calculations in-house to estimate the chance of the technology succeeding. Once Engineering gives us the green light, it’s my responsibility to make the budget and staff available for the pilot project.

Van Oord has a strong incentive to succeed in developing the slip joint technology.

‘No single enterprise has all the know-how needed to develop a complete innovation programme on its own. I look for links between innovative concepts in the market and Van Oord’s innovation programme.’

Incentive to succeed

‘The slip joint is a good example of how different partners in the offshore wind industry can cooperate to make improvements. Van Oord has been involved

Wouter Dirks

Manager Engineering & Estimating Energy

‘My job involves managing innovation projects that focus mainly on offshore wind technology. Although that technology has been around for many years, we keep looking for new ways to make offshore wind as appealing as possible as part of the energy mix of the future.’

alone is not enough

Why technology

Interview

Eco scour protection:

creating reef systems

The seabed surrounding the two Borssele V wind turbines will be fitted with eco scour protection. Van Oord is using this sustainable technology to explore how nature and renewable energy generation can be mutually enhancing. Oysters will be planted on the protective layer of rock on the seabed to improve biodiversity and the natural habitat for aquatic wildlife.

Slip joint: no bolts

The slip joint is an alternative connection between an offshore wind monopile and a turbine. It works the same way as two upside-down paper cups stacked on top of each other. The connection is based on friction, with the weight ensuring firmness and stability. Installation takes place simply by sliding the wind turbine’s foundation elements over the monopile, without having to use grout or bolts.

Borssele Site V

Van Oord is putting innovation into practice, including the slip joint and ecological improvements. But how do innovations go from the drawing board to the real world? Wouter Dirks, responsible for Research, Development and Innovation at Van Oord, says that innovation would be impossible without cooperation.

Marine ingenuity

Turning innovations

into reality

A new sustainable energy zone is under construction some 20 kilometres off the coast of the Dutch Province of Zeeland: Borssele Wind Farm Site V.

After graduating in Mining and Petroleum Engineering from Delft University of Technology, Wouter accepted a job as a Geotechnical Engineer in 1990 with one of Van Oord’s legal predecessors.

During his almost 30-year career, Wouter has worked in various positions in Engineering and as a Project Manager. It was under his supervision that Van Oord began setting up its Environmental Engineering department in 2004. Since 2018, Wouter has focused exclusively on Research, Development and Innovation.

About Wouter Dirks

Partner-up

‘The following step in our innovation programme is to look further ahead: what will the offshore wind market be up to in the next 10 to 15 years? Without the right partners and initiatives like the Van Oord Innovation Challenge, we would not be able to prepare for the future. I cannot emphasise enough just how important cooperation is to success in my field. I’m realistic. We aren’t the only ones coming up with smart solutions – they’re being developed by other, external parties all over the world. So we have to use partnerships, challenges and other knowledge-sharing initiatives to obtain the expertise that we need for our innovation programme.’

In-house power house

‘Right now our innovation programme is focused on the short term: what can we achieve in the next five years? I work on various trials concentrating on different themes, for example noise reduction, pile-driving hammers or floating installation, and I link them to objectives. Within each theme, I collaborate with ambassadors who inspire one another and propose new techniques. We take the ambassadors’ findings and recommendations and use them as a basis for planning our investments in new innovation projects.’

It is in our nature to care

‘Van Oord has spent several years now testing how to restore or support wildlife at sea. We have been working with Dutch teaching and research institutions to develop methods for large-scale oyster cultivation and planting. For example, we’re performing laboratory tests with various oyster species, substrates and water conditions, so that besides offshore construction, we can create opportunities to improve aquatic nature and biodiversity at the same time.’

‘No single enterprise has all the know-how needed to develop a complete innovation programme on its own. I look for links between innovative concepts in the market and Van Oord’s innovation programme.’

Incentive to succeed

‘The slip joint is a good example of how different partners in the offshore wind industry can cooperate to make improvements. Van Oord has been involved in developing the slip joint for more than six years. After its introduction, we started off making drawings and calculations in-house to estimate the chance of the technology succeeding. Once Engineering gives us the green light, it’s my responsibility to make the budget and staff available for the pilot project.

Van Oord has a strong incentive to succeed in developing the slip joint technology. An offshore wind project is carried out in different steps: first we drive a monopile into the seabed, then we install the transition piece, then the tower, and then the gondola and the rotor blades. Each and every step takes time and is vulnerable to weather conditions. By reducing or simplifying the steps, for example with the help of the slip joint, we can achieve a considerable cost saving.’

Wouter Dirks

Manager Engineering & Estimating Energy

‘My job involves managing innovation projects that focus mainly on offshore wind technology. Although that technology has been around for many years, we keep looking for new ways to make offshore wind as appealing as possible as part of the energy mix of the future.’

Why technology alone

is not enough

Interview

Human intervention has caused the European flat oyster (Ostrea edulis) to disappear almost entirely from the North Sea. Innovation programmes such as Borssele V and The Rich North Sea explore whether North Sea wind farms can create a suitable habitat for the recovery of this species.

Eco scour protection

Facts & figures

Eco scour protection:

creating reef systems

The seabed surrounding the two Borssele V wind turbines will be fitted with eco scour protection. Van Oord is using this sustainable technology to explore how nature and renewable energy generation can be mutually enhancing. Oysters will be planted on the protective layer of rock on the seabed to improve biodiversity and the natural habitat for aquatic wildlife.

The installation cycle is several hours shorter

The slip joint makes installation possible both above and below the surface; other connections are only possible above the water

The slip joint itself is maintenance-free

Slip joint Facts & figures

Slip joint: no bolts

The slip joint is an alternative connection between an offshore wind monopile and a turbine. It works the same way as two upside-down paper cups stacked on top of each other. The connection is based on friction, with the weight ensuring firmness and stability. Installation takes place simply by sliding the wind turbine’s foundation elements over the monopile, without having to use grout or bolts.

Eco scour protection:

creating reef systems

Slip joint:

no bolts

Borssele V has been designated as an innovation site within the Borssele Wind Farm Zone. The Two Towers consortium, consisting of Van Oord, Investri Offshore and Green Giraffe, has been awarded the project and thus given a unique opportunity to test and demonstrate advanced technologies. The offshore wind farm zone is located about 20 kilometres off the coast of Walcheren and is surrounded by the other four Borssele sites. Site V will have two 9.5 MW turbines. On the completion of Borssele V in 2021, the two turbines will supply 25,000 households with green energy. Once the entire Borssele wind farm is fully operational, it will deliver renewable energy to 2 million households.

Van Oord is putting innovation into practice, including the slip joint and ecological improvements. But how do innovations go from the drawing board to the real world? Wouter Dirks, responsible for Research, Development and Innovation at Van Oord, says that innovation would be impossible without cooperation.

Borssele Site V

A new sustainable energy zone is under construction some 20 kilometres off the coast of the Dutch Province of Zeeland: Borssele Wind Farm Site V.

Turning innovations into reality

Marine ingenuity