Mauritania

Senegal

Nigeria

Saly is the beating heart of Senegalese tourism on the Petite Côte. Tourism is the main source of income for its 20,000 inhabitants. Erosion gradually reduces the size of the beaches and is therefore a threat to Senegal's most popular coastal resort. Using a trailing suction hopper dredger, we will apply some 550,000 cubic metres of sand over a length of 4.5 kilometres of beach. This way, the replenished beaches can once more welcome the sun worshippers.

Van Oord is building groynes and detached breakwaters along a 4.5-kilometres long stretch of the coast to make it safe again. A local quarry has been contracted to supply more than 200,000 tonnes of rock. That way, a large portion of the contract value flows back into the local economy. In addition, we are using local subcontractors and 40% of our project staff are Senegalese nationals. The World Bank is funding the project.

In order to make future generations aware of the dangers of litter to health and the environment, Van Oord provided 800 pupils at a government school in Saly with background information. The project team then joined the schoolchildren to collect plastic litter and Van Oord used the proceeds to purchase school supplies such as exercise books, pencils and pens.

Creating new opportunities

for tourism

Benefit to the local

economy

Educating schoolchildren about collecting plastic litter

The Senegalese coastal town of Saly is one of the most popular tourist attractions in West Africa. Like many other places along the west coast of Africa, Saly’s coastal defences have been weakened by erosion. Flood damage would have major consequences for the fragile local economy. The beaches are also eroding, leading to a decline in tourism and the corresponding revenue. Van Oord is building groynes and detached breakwaters to protect the land and will be replenishing the beaches to provide more space for tourists.

Strengthening coastal defences and enlarging beaches for Saly

Bigger ore ships gain access to the port of Nouadhibou

Future-proofing Nigeria's oil and gas infrastructure

Van Oord built the landfall for the 20-inch OSO QIT oil pipeline and the 24-inch Idoho CRA gas pipeline. The oil pipeline transports crude oil from the Oso field in the Bight of Bonny to the Qua Iboe Terminal for processing. The gas released during the extraction of the oil is not burnt off. It is transported via the gas pipeline to the mainland to be used as an energy supply.

Van Oord offered dozens of local unskilled people the opportunity to follow an external vocational training course. After that, they could play a role in the operations or on the project site in a variety of positions. At the start of the project, an inventory was also made of all the products and services required. A survey was then conducted among local residents and businesses to ensure that the community derives maximum benefit from Van Oord's presence in the area.

Self-propelled cutter suction dredger Athena expertly dredged a five-kilometre trench in the seabed. A pipe-laying vessel then installed the two pipelines. Because the Athena is equipped with a swell-compensated spud carriage, it can still dredge even in difficult conditions with a lot of tidal action. Sister ship Artemis is also equipped with this unique system. Watch an animation here.

Sustainable solution

for released gas

Training opportunities for the local population

Best vessel for the job

Nigeria is rich in mineral resources, including oil, gas, coal, tin, iron and zinc. Proceeds from the sale of oil and gas form the backbone of its national economy. A good oil and gas infrastructure is therefore crucial to the country. Van Oord spent the first six months of this year constructing a landfall there for two new pipelines. The Oso field is located in offshore Nigeria, in Akwa Ibom State, in the Bight of Bonny. The field is approximately 12 miles from shore and 30 miles southwest of the onshore Qua Iboe Terminal (QIT).

Future-proofing Nigeria's oil and gas infrastructure

Strengthening coastal defences and enlarging beaches for Saly

Bigger ore ships gain access to the port of Nouadhibou

In order to reduce plastic waste, all project employees were given stainless steel water bottles, which can be refilled using water dispensers. In this way the use of plastic water bottles will be prevented. The project team is busy initialising more initiatives to also reduce plastic waste in vicinity of the site office and is preparing for a cleanup involving local authorities and employees.

Two trailing suction hopper dredgers, one of which is owned by Van Oord, will be deployed for the dredging work. We will be deploying our flagship HAM 318. It is the largest of this type of dredgers in Van Oord's cutting-edge fleet. The vessel was extended by 52 metres to 228 metres in 2008. This increased its hopper capacity from 23,783 to 37,500 cubic metres.

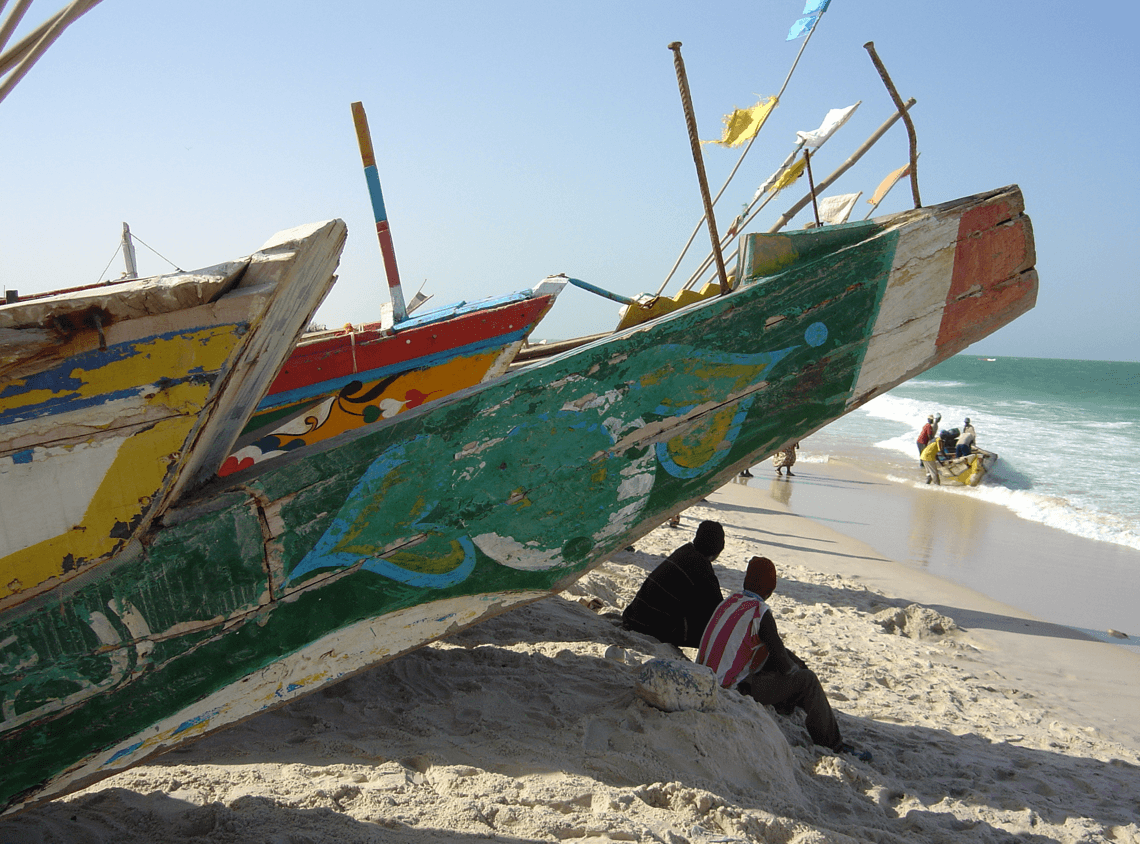

Our vessels operate 24 hours a day, seven days a week. But local fishermen also ply the waterways day and night. Many of them use wooden boats which are not visible on the radar and moreover have no lights. In order to create the safest possible situation, we distribute small radar reflectors and LED lighting to the fishermen to increase their visibility.

Reducing plastic waste

Van Oord's largest trailing suction hopper dredger

Care for local fishermen

Mauritania is the second-largest exporter of iron ore on the African continent. Van Oord is deepening and widening the access channel and turning basin of a large ore export facility in Nouadhibou. Thanks to the deeper and wider port access, ships with a capacity of up to 250,000 tonnes will be able to access the newly built berths. This will strengthen the country's position as an exporter and benefit the economy.

Bigger ore ships gain access to the port of Nouadhibou

Future-proofing

Nigeria's oil and gas infrastructure

Strengthening coastal defences and enlarging beaches for Saly

Mauritania

Senegal

Nigeria

skies

Under

African

Van Oord operates worldwide. In West Africa, we are using our expertise to strengthen coastal defences in Senegal, to construct a landfall for an oil and gas pipeline in Nigeria and provide deeper port access in Mauritania.

Saly is the beating heart of Senegalese tourism on the Petite Côte. Tourism is the main source of income for its 20,000 inhabitants. Erosion gradually reduces the size of the beaches and is therefore a threat to Senegal's most popular coastal resort. Using a trailing suction hopper dredger, we will apply some 550,000 cubic metres of sand over a length of 4.5 kilometres of beach. This way, the replenished beaches can once more welcome the sun worshippers.

Creating new opportunities for tourism

Van Oord is building groynes and detached breakwaters along a 4.5-kilometres long stretch of the coast to make it safe again. A local quarry has been contracted to supply more than 200,000 tonnes of rock. That way, a large portion of the contract value flows back into the local economy. In addition, we are using local subcontractors and 40% of our project staff are Senegalese nationals. The World Bank is funding the project.

Benefit to the local

economy

In order to make future generations aware of the dangers of litter to health and the environment, Van Oord provided 800 pupils at a government school in Saly with background information. The project team then joined the schoolchildren to collect plastic litter and Van Oord used the proceeds to purchase school supplies such as exercise books, pencils and pens.

Educating schoolchildren about collecting plastic litter

The Senegalese coastal town of Saly is one of the most popular tourist attractions in West Africa. Like many other places along the west coast of Africa, Saly’s coastal defences have been weakened by erosion. Flood damage would have major consequences for the fragile local economy. The beaches are also eroding, leading to a decline in tourism and the corresponding revenue. Van Oord is building groynes and detached breakwaters to protect the land and will be replenishing the beaches to provide more space for tourists.

Strengthening coastal defences and enlarging beaches for Saly

Van Oord built the landfall for the 20-inch OSO QIT oil pipeline and the 24-inch Idoho CRA gas pipeline. The oil pipeline transports crude oil from the Oso field in the Bight of Bonny to the Qua Iboe Terminal for processing. The gas released during the extraction of the oil is not burnt off. It is transported via the gas pipeline to the mainland to be used as an energy supply.

Sustainable solution

for released gas

Van Oord offered dozens of local unskilled people the opportunity to follow an external vocational training course. After that, they could play a role in the operations or on the project site in a variety of positions. At the start of the project, an inventory was also made of all the products and services required. A survey was then conducted among local residents and businesses to ensure that the community derives maximum benefit from Van Oord's presence in the area.

Training opportunities for the local population

Self-propelled cutter suction dredger Athena expertly dredged a five-kilometre trench in the seabed. A pipe-laying vessel then installed the two pipelines. Because the Athena is equipped with a swell-compensated spud carriage, it can still dredge even in difficult conditions with a lot of tidal action. Sister ship Artemis is also equipped with this unique system. Watch an animation here.

Best vessel for the job

Nigeria is rich in mineral resources, including oil, gas, coal, tin, iron and zinc. Proceeds from the sale of oil and gas form the backbone of its national economy. A good oil and gas infrastructure is therefore crucial to the country. Van Oord spent the first six months of this year constructing a landfall there for two new pipelines. The Oso field is located in offshore Nigeria, in Akwa Ibom State, in the Bight of Bonny. The field is approximately 12 miles from shore and 30 miles southwest of the onshore Qua Iboe Terminal (QIT).

Future-proofing Nigeria's oil and gas infrastructure

In order to reduce plastic waste, all project employees were given stainless steel water bottles, which can be refilled using water dispensers. In this way the use of plastic water bottles will be prevented. The project team is busy initialising more initiatives to also reduce plastic waste in vicinity of the site office and is preparing for a cleanup involving local authorities and employees.

Reducing plastic waste

Two trailing suction hopper dredgers, one of which is owned by Van Oord, will be deployed for the dredging work. We will be deploying our flagship HAM 318. It is the largest of this type of dredgers in Van Oord's cutting-edge fleet. The vessel was extended by 52 metres to 228 metres in 2008. This increased its hopper capacity from 23,783 to 37,500 cubic metres.

Van Oord's largest trailing suction hopper dredger

Our vessels operate 24 hours a day, seven days a week. But local fishermen also ply the waterways day and night. Many of them use wooden boats which are not visible on the radar and moreover have no lights. In order to create the safest possible situation, we distribute small radar reflectors and LED lighting to the fishermen to increase their visibility.

Care for local fishermen

Mauritania is the second-largest exporter of iron ore on the African continent. Van Oord is deepening and widening the access channel and turning basin of a large ore export facility in Nouadhibou. Thanks to the deeper and wider port access, ships with a capacity of up to 250,000 tonnes will be able to access the newly built berths. This will strengthen the country's position as an exporter and benefit the economy.

Bigger ore ships gain access to the port of Nouadhibou