to process

optimisation

Develop a fully automatic system for installing a rock structure on the seabed: that is the challenge facing Van Oord’s Subsea Rock Installation (SRI) specialists. The most ingenious people, all working in different disciplines, have joined forces in a SRI automation project team.

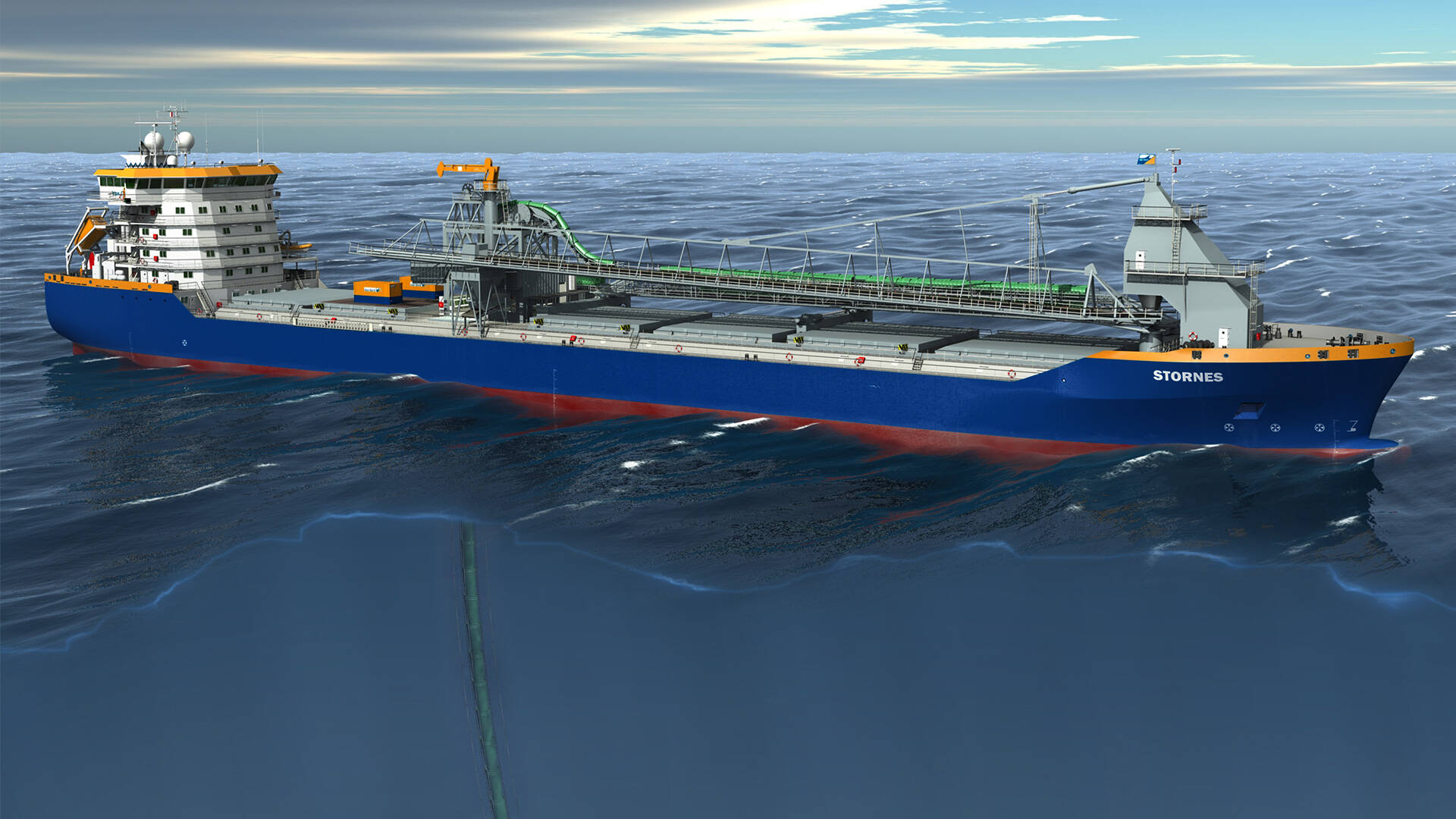

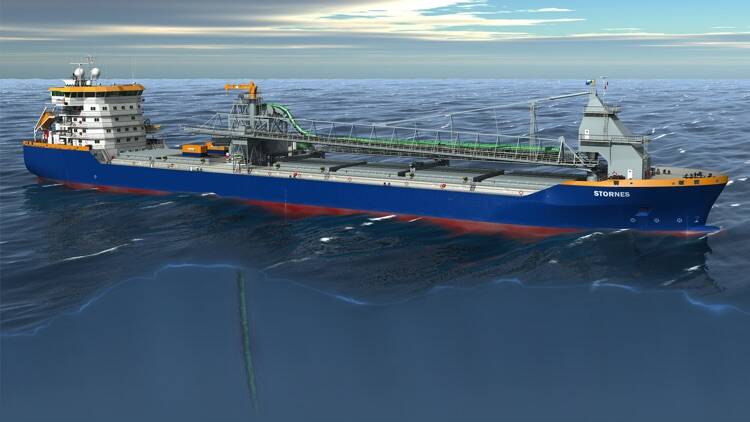

expertise and know-how in different disciplines.’ Van Oord’s new subsea rock installation vessel Bravenes, which will become operational in 2018, will also be equipped with the new software. ‘These innovations mean we can offer our clients high-quality rock installation,’ Joep concludes.

quality and production by means of automation.’

Benefits

Van Oord’s clients will benefit from this automation project. ‘We’ll be able to install rock at higher speeds and with greater precision, resulting in less waste, a shorter execution period and lower costs,’ says Joep. ‘This is a great example of what Van Oord can do when we combine our experience,

Van Oord has led the market in subsea rock installation for more than thirty years. ‘We managed to maintain that position by continuously challenging ourselves and by improving our expertise,’ says Joep Athmer, Area Director Offshore at Van Oord. ‘We want to offer our clients the smartest techniques and the most cost-effective solution, and that means we never stop coming up with new ideas. The latest technological innovation we’re working on is how to improve SRI

the crew’s full attention. ‘The point of the SRI automation project is to automate all on-board processes required to install a rock structure according to the installation plan,’ says Erik-Jan Brouwer, Production Engineer SRI at Van Oord.

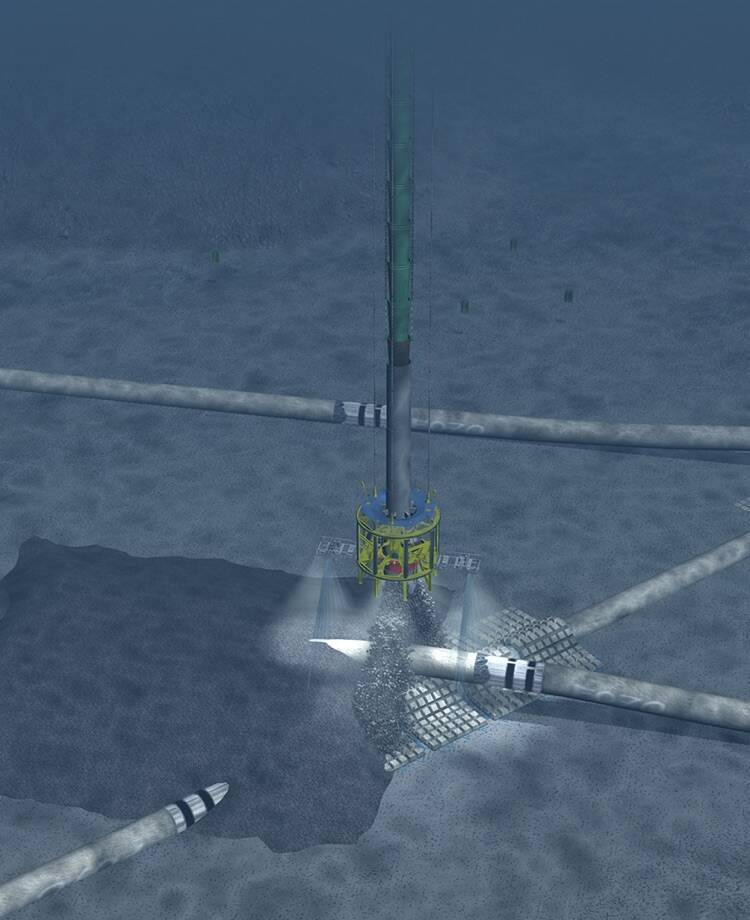

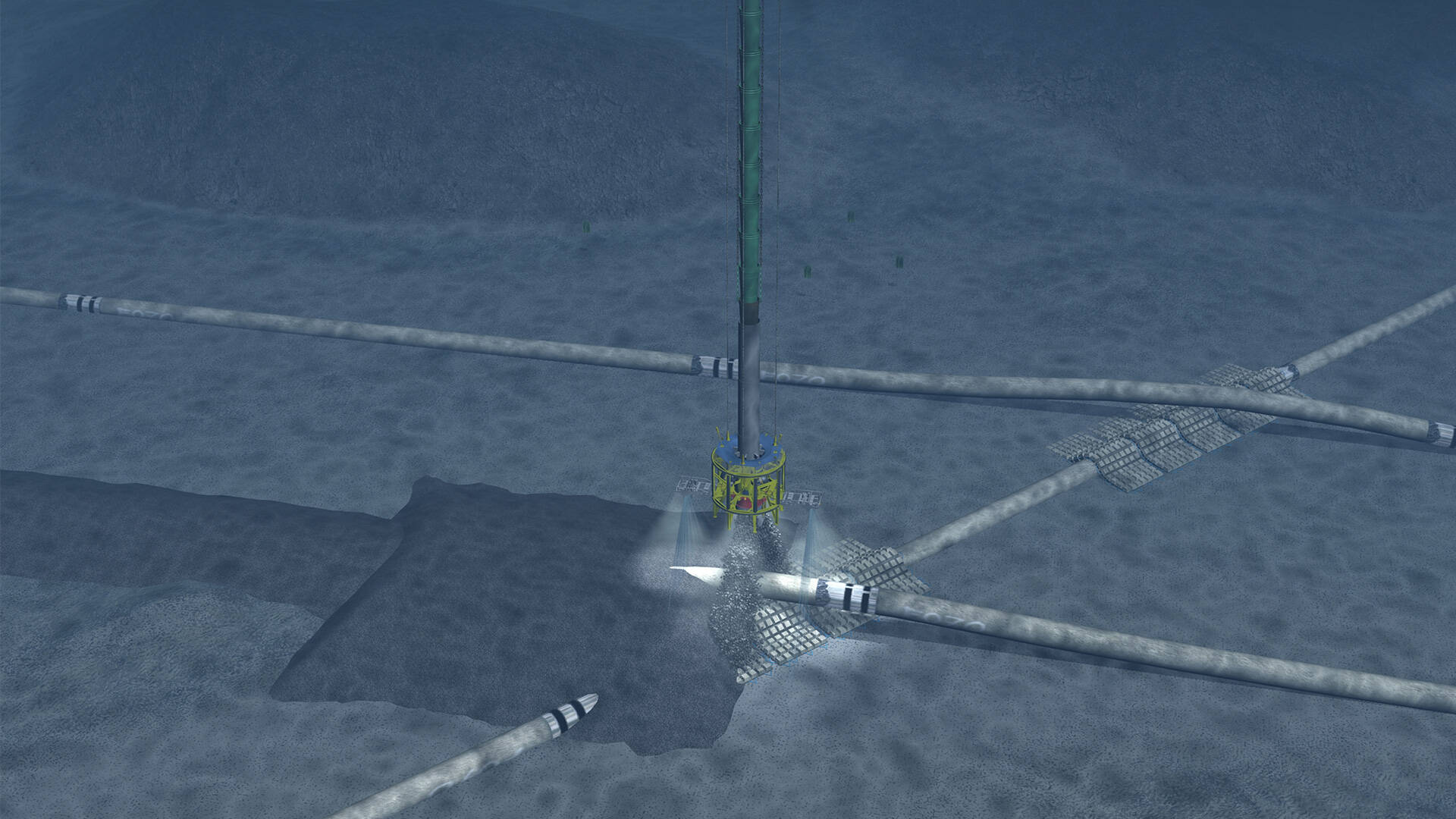

The flexibility of the fallpipe combined with a powerful Remotely Operated Vehicle (ROV) allow the crew to place material on the seabed with high precision at depths of between -3 to -2,200 metres. Controlling these systems requires extreme accuracy and

Fallpipe specialists

Van Oord operates two flexible fallpipe vessels. The company developed and patented its flexible fallpipe system, consisting of an articulated string of cone-shaped bottomless buckets, in 1985.

Autopilot

‘It’s like subsea rock installation on autopilot,’ says Erik-Jan. ‘This new system allows us to install a rock structure fully automatically and with high precision.’ A multidisciplinary team within Van Oord has been working on the project for two years now. Erik-Jan continues: ‘The systems on board use predetermined data to calculate the exact amount of rock required at any specific location on the seabed. The software manages the entire rock installation process without human intervention or post-installation adjustment. On recently executed SRI projects, we successfully deployed flexible fallpipe vessels, which have already been equipped with this new software.’

Develop a fully automatic system for installing a rock structure on the seabed: that is the challenge facing Van Oord’s Subsea Rock Installation (SRI) specialists. The most ingenious people, all working in different disciplines, have joined forces in a SRI automation project team.

to process

optimisation

Joep Athmer

Area Director

Offshore at Van Oord

expertise and know-how in different disciplines.’ Van Oord’s new subsea rock installation vessel Bravenes, which will become operational in 2018, will also be equipped with the new software. ‘These innovations mean we can offer our clients high-quality rock installation,’ Joep concludes.

quality and production by means of automation.’

Benefits

Van Oord’s clients will benefit from this automation project. ‘We’ll be able to install rock at higher speeds and with greater precision, resulting in less waste, a shorter execution period and lower costs,’ says Joep. ‘This is a great example of what Van Oord can do when we combine our experience,

Van Oord has led the market in subsea rock installation for more than thirty years. ‘We managed to maintain that position by continuously challenging ourselves and by improving our expertise,’ says Joep Athmer, Area Director Offshore at Van Oord. ‘We want to offer our clients the smartest techniques and the most cost-effective solution, and that means we never stop coming up with new ideas. The latest technological innovation we’re working on is how to improve SRI

Erik-Jan Brouwer

Production Engineer SRI at Van Oord

the crew’s full attention. ‘The point of the SRI automation project is to automate all on-board processes required to install a rock structure according to the installation plan,’ says Erik-Jan Brouwer, Production Engineer SRI at Van Oord.

The flexibility of the fallpipe combined with a powerful Remotely Operated Vehicle (ROV) allow the crew to place material on the seabed with high precision at depths of between -3 to -2,200 metres. Controlling these systems requires extreme accuracy and

Fallpipe specialists

Van Oord operates two flexible fallpipe vessels. The company developed and patented its flexible fallpipe system, consisting of an articulated string of cone-shaped bottomless buckets, in 1985.

Autopilot

‘It’s like subsea rock installation on autopilot,’ says Erik-Jan. ‘This new system allows us to install a rock structure fully automatically and with high precision.’ A multidisciplinary team within Van Oord has been working on the project for two years now. Erik-Jan continues: ‘The systems on board use predetermined data to calculate the exact amount of rock required at any specific location on the seabed. The software manages the entire rock installation process without human intervention or post-installation adjustment. On recently executed SRI projects, we successfully deployed flexible fallpipe vessels, which have already been equipped with this new software.’