Malte Paul

Logistics & Construction Manager for Arkona at E.ON

‘Van Oord has successfully managed the challenging Baltic seabed, handled XL monopiles and implemented noise mitigation, all within a very short time period. The Arkona offshore wind project is proceeding significantly faster than expected and will be fully operational in 2019.’

The Arkona offshore wind project saw heavy lift installation vessel Svanen return to the German Baltic Sea for a home match. The challenge? To install heavy monopiles, weighing up to 1,200 tonnes each, in an unpredictable seabed, while limiting the impact on the surroundings. The Svanen passed with flying colours.

the jacuzzi

Moritz Horn

Managing Director of

Van Oord Offshore Wind Germany

It could be clay, sand, rock, limestone or a combination of all four. Then there’s the fact that the monopiles for Arkona weighed up to 1,200 tonnes and had a maximum length of 81 metres. The Svanen had never installed monopiles that long and heavy before. We managed to hammer all sixty monopiles up to 40 metres into the seabed, in accordance with the highest quality and safety standards. The installation strategy was based on the special feeder concept, with the foundation components being floated to the Svanen at the installation site.’

Besides meeting the demand for floating installation of the large, heavy monopiles in the Baltic seabed, a major requirement was to minimise the impact of installation on marine species. By deploying the Svanen and applying several noise mitigating methods, Van Oord offered the best solution for client E.ON and was contracted to install sixty monopiles and transition pieces.

Challenging but familiar waters

The Svanen has played a leading role in several Baltic projects. ‘The Baltic Sea has a complicated seabed,’ says Moritz Horn, Managing Director of Van Oord Offshore Wind Germany. ‘It consists of so many different soil types that it’s hard to say what we’ll encounter during pile-driving.

Noise mitigation

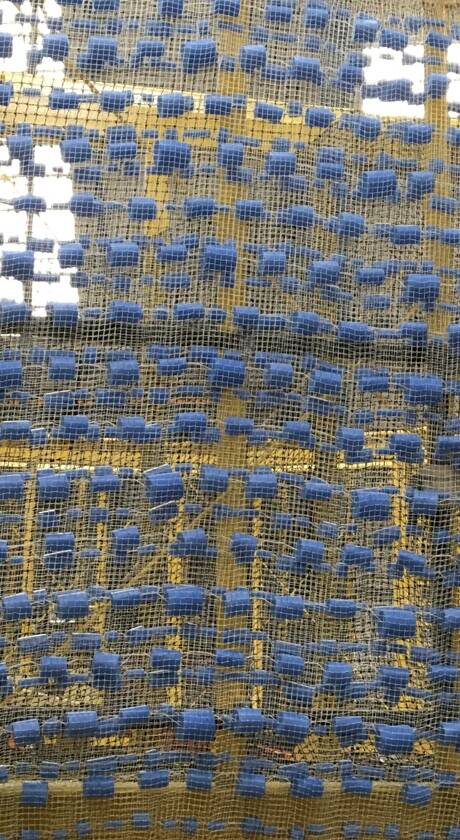

The noise that goes along with pile-driving can negatively impact marine mammals and potentially cause hearing loss in porpoises. ‘Our mitigation strategy was to reduce underwater noise and keep porpoises outside the piling zone,’ explains Moritz. ‘During pile-driving operations, we used a hydro sound damper attached to the piling frame on the Svanen. It consists of a net containing air-filled elastic balloons and special PE foam elements that form a curtain around the monopile and reduce underwater noise.’ Van Oord also laid two temporary bubble curtains on the seabed around the pile-driving location. The curtains released bubbles of air that rose to the surface to form a barrier around the Svanen, breaking acoustic waves and further reducing noise levels.

FaunaGuard

To keep porpoises outside the piling zone, Van Oord used its innovative FaunaGuard system, which it developed in-house. This acoustic device safely and temporarily deters marine fauna. ‘We used the FaunaGuard’s special porpoise module on the Arkona project,’ Moritz explains. ‘We triggered the module, which emits special underwater acoustic signals created specifically for porpoises, forty minutes before pile-driving started. The signal keeps them at a safe distance from the construction site and protects them against potential hearing loss. The FaunaGuard’s excellent results on previous offshore wind projects, including Gemini and Luchterduinen, convinced the German Maritime and Hydrographic Agency that it would have the best effect.’

Copyright: AWE Arkona-Windpark-Entwicklungs-GmbH

Outcome: offshore wind farm Arkona will be fully operational in 2019, when it will start supplying renewable energy to 400,000 households.

Location: located in the German Baltic Sea, more than 35 kilometres north of Rügen Island.

Scope: transport and installation of sixty monopiles and transition pieces. To install the foundations, Van Oord used its heavy lift installation vessel Svanen.

Client: E.ON (50%) and Statoil (50%).

Malte Paul

Logistics & Construction Manager for Arkona at E.ON

‘Van Oord has successfully managed the challenging Baltic seabed, handled XL monopiles and implemented noise mitigation, all within a very short time period. The Arkona offshore wind project is proceeding significantly faster than expected and will be fully operational in 2019.’

The Arkona offshore wind project saw heavy lift installation vessel Svanen return to the German Baltic Sea for a home match. The challenge? To install heavy monopiles, weighing up to 1,200 tonnes each, in an unpredictable seabed, while limiting the impact on the surroundings. The Svanen passed with flying colours.

the jacuzzi

Moritz Horn

Managing Director of

Van Oord Offshore Wind Germany

It could be clay, sand, rock, limestone or a combination of all four. Then there’s the fact that the monopiles for Arkona weighed up to 1,200 tonnes and had a maximum length of 81 metres. The Svanen had never installed monopiles that long and heavy before. We managed to hammer all sixty monopiles up to 40 metres into the seabed, in accordance with the highest quality and safety standards. The installation strategy was based on the special feeder concept, with the foundation components being floated to the Svanen at the installation site.’

Besides meeting the demand for floating installation of the large, heavy monopiles in the Baltic seabed, a major requirement was to minimise the impact of installation on marine species. By deploying the Svanen and applying several noise mitigating methods, Van Oord offered the best solution for client E.ON and was contracted to install sixty monopiles and transition pieces.

Challenging but familiar waters

The Svanen has played a leading role in several Baltic projects. ‘The Baltic Sea has a complicated seabed,’ says Moritz Horn, Managing Director of Van Oord Offshore Wind Germany. ‘It consists of so many different soil types that it’s hard to say what we’ll encounter during pile-driving.

Noise mitigation

The noise that goes along with pile-driving can negatively impact marine mammals and potentially cause hearing loss in porpoises. ‘Our mitigation strategy was to reduce underwater noise and keep porpoises outside the piling zone,’ explains Moritz. ‘During pile-driving operations, we used a hydro sound damper attached to the piling frame on the Svanen. It consists of a net containing air-filled elastic balloons and special PE foam elements that form a curtain around the monopile and reduce underwater noise.’ Van Oord also laid two temporary bubble curtains on the seabed around the pile-driving location. The curtains released bubbles of air that rose to the surface to form a barrier around the Svanen, breaking acoustic waves and further reducing noise levels.

FaunaGuard

To keep porpoises outside the piling zone, Van Oord used its innovative FaunaGuard system, which it developed in-house. This acoustic device safely and temporarily deters marine fauna. ‘We used the FaunaGuard’s special porpoise module on the Arkona project,’ Moritz explains. ‘We triggered the module, which emits special underwater acoustic signals created specifically for porpoises, forty minutes before pile-driving started. The signal keeps them at a safe distance from the construction site and protects them against potential hearing loss. The FaunaGuard’s excellent results on previous offshore wind projects, including Gemini and Luchterduinen, convinced the German Maritime and Hydrographic Agency that it would have the best effect.’