Experts point

of view

Sustainability

Quieter pile

driving

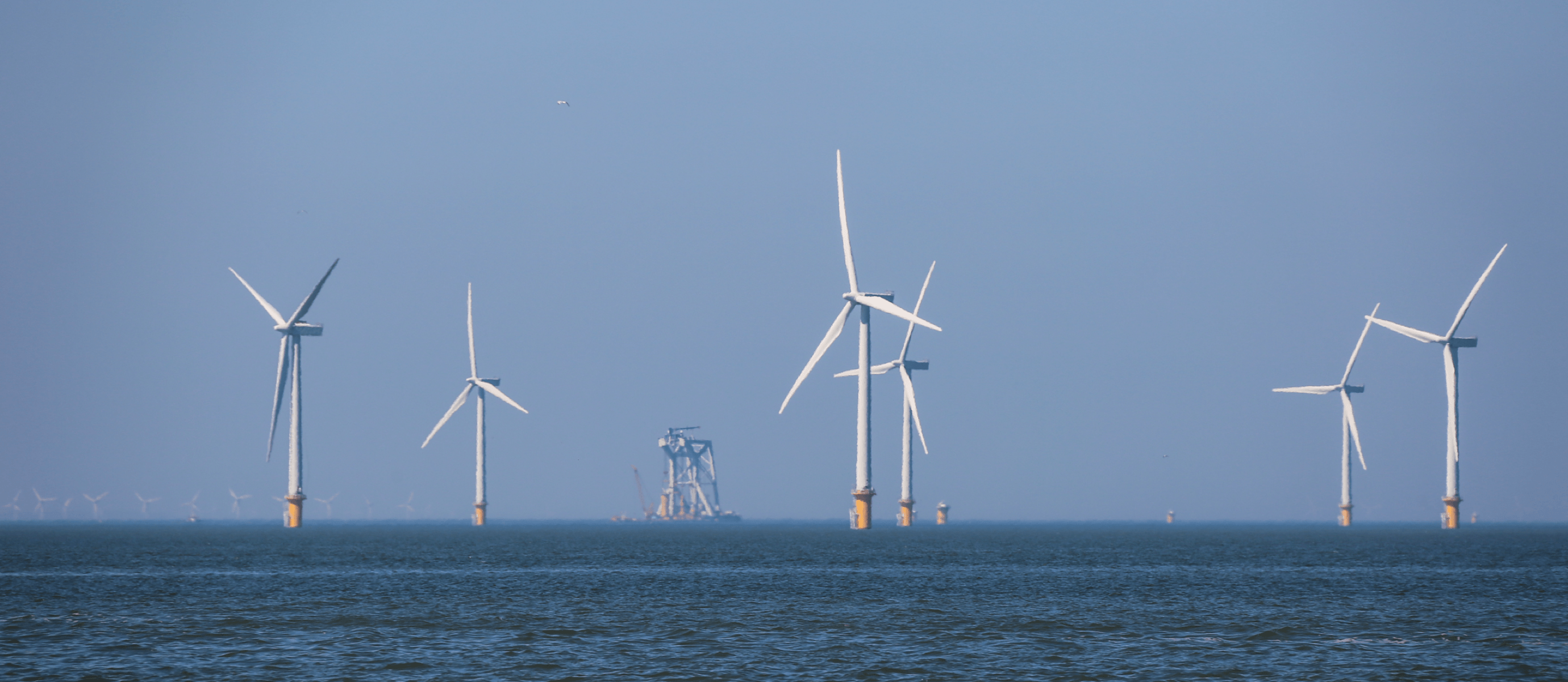

Our society needs offshore wind projects to meet its renewable energy targets. Unfortunately, the noise that such construction projects generate below the water surface can have an impact on marine life. That’s why we invest in the AdBm Noise Mitigation System.

Jan Willem Elleswijk

Lianne te Raa &

Frank van den Berg

Trials needed for successful roll-out of innovations

The added value of an innovation becomes clear when it’s effectively applied in a series of trials. Such trials show whether the system does what it’s supposed to do, what it means to use the system on an actual project, and what it costs. All this information is essential for the successful roll-out of the innovation. As a result, the trials represent an important milestone in the ongoing development of innovations.

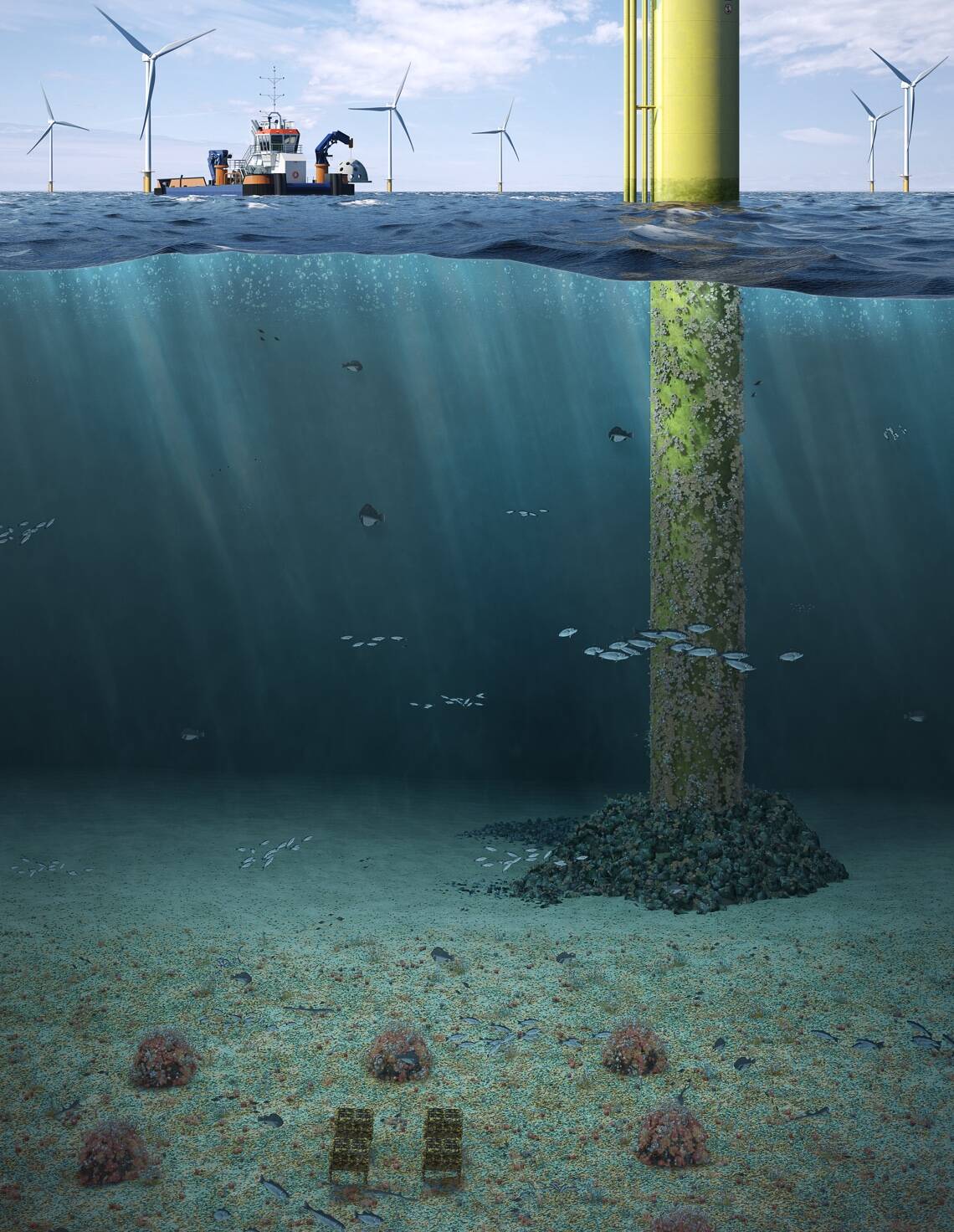

Multiple use of space

The Netherlands Environmental Assessment Agency has calculated that the North Sea can accommodate about 12,000 wind turbines each with a capacity of 5 MW. Building wind farms in the North Sea that will deliver 60 GW of power requires clever use of space. We’re working on these sorts of topics as well. For example, a wind farm can do double duty as an incubator for marine wildlife. That way we facilitate the energy transition and we support biodiversity in the North Sea.

NMS made possible thanks to the assistance

of TKI Wind op Zee

For a long time it was unclear whether underwater noise affected marine life and, if so, to what extent. Much research has been done in recent years to find answers to these important questions. We facilitate such research and encourage innovations that reduce the impact of underwater noise. Our aim is to help make the energy transition possible and to accelerate it, and it was from that perspective that we recognised the potential of the NMS. That is in part why we subsidised its development and the associated trials.

The NMS and similar innovations are crucial

to the energy transition

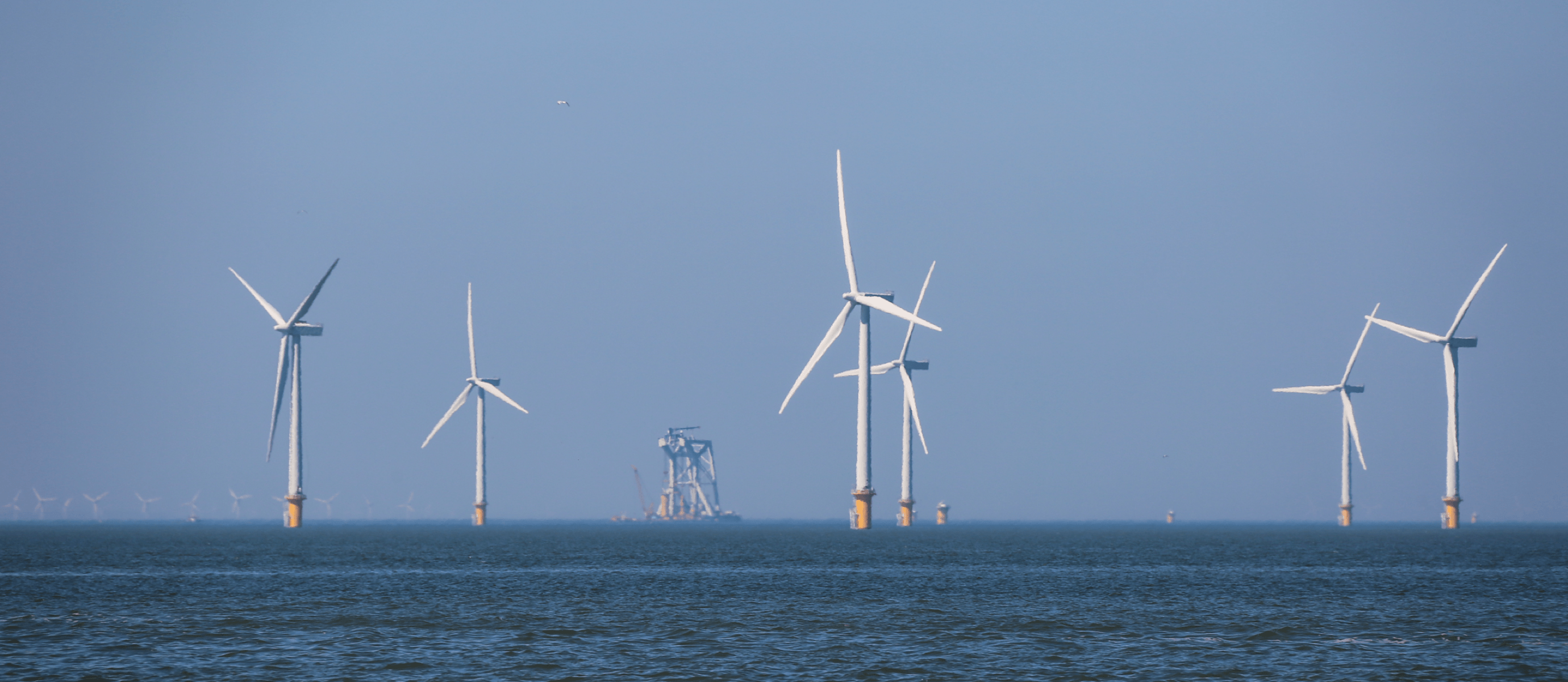

The Climate Agreement focuses on lowering carbon emissions by 95% in 2050 compared to 1990 levels. Our government is therefore committed to expanding offshore wind energy. But this raises other issues, for example the problem of underwater noise during construction. Installing wind turbine foundations in the North Sea almost always requires pile driving. Without precautionary measures this methodology impacts marine mammals. To protect them, there are strict rules for noise emissions at sea, based on the aforementioned research evidence. Violating the standards is not an option but noise mitigation systems and other smart solutions are.

Bob Meijer

Our aim is to help make the energy transition possible and to accelerate it, and it was from that perspective that we recognised the potential of the NMS.

The construction of offshore wind farms raises concerns about marine life, and the sector is subject to strict rules in that regard. That’s why noise mitigation systems are so important. TKI Wind op Zee supported the development of the NMS and the associated trials. Its director, Bob Meijer, shares his thoughts.

TKI Wind op Zee

Bob Meijer

From data to useful information

The German firm of consulting engineers ITAP registered the underwater noise during the trials. They did so based on a measurement plan that we developed. Their readings yielded loads of data. How do you turn data into useful information? We analysed and interpreted the outcomes and discussed any unexpected results with Van Oord and AdBm Technologies. The specialists involved were eager to share information about what they do, why they do it, and how. We complemented one another's knowledge and expertise perfectly.

Knowing what to expect

Because the NMS is new, we wanted to assess its estimated noise reduction capability. We did this by developing a specific model for it. The data delivered by such models is absolutely essential in the preparation phase of offshore wind projects. After all, you don't want to have to stop construction of a wind farm because you've exceeded the standards for underwater noise. You want to know what to expect so that you can plan ahead.

Bob Meijer

Jan Willem Elleswijk

Condition of seabed important factor

in NMS noise reduction

The trials showed that our model had given us a fairly accurate prediction of the NMS's noise reduction capability. We also learned that the NMS is most effective at sites where the seabed itself absorbs a lot of noise. We further saw that the results of our model depend heavily on the precise composition of the seabed at the construction site. What type of soil is it, how is it stratified, what is its absorption capacity? Such factors determine how sound is transmitted through the seabed, whether it reverberates to the water column and, if so, to what extent and where.

Nurturing industry with the power of innovation

We help companies such as Van Oord to make the right choices as they develop and apply measures to reduce underwater noise. Have you ever dived into the North Sea? If so, then you know that you can’t see a thing. That’s why marine animals there depend on their hearing to find food, to communicate with one another, to find mates, and so on. Human noise can disturb and possibly even damage marine wildlife, so we need to set and respect limits on underwater noise.

Lianke te Raa & Frank van den Berg

The specialists involved were eager to share information about what they do, why they do it, and how. We complemented one another's knowledge and expertise perfectly.

The independent research organisation TNO accumulates knowledge and advises authorities and businesses, including those in the offshore sector, on how to apply that knowledge in the field. Underwater noise specialists Lianke te Raa and Frank van den Berg were involved in the demonstration project of the NMS from the very beginning. They share their thoughts on their experience.

TNO

Lianke te Raa &

Frank van den Berg

3

5

4

2

1

Always room for improvement

We’re using all available knowledge to improve the NMS in cooperation with our partner AdBm Technologies. This Texas start-up develops and produces the NMS’s acoustic resonators, which are adjusted to absorb the most harmful underwater noise. One of our engineers visited AdBm’s experts in June to observe their testing of new system configurations. Each and every step delivers new knowledge and is therefore valuable. Together, we are optimising the system’s performance.

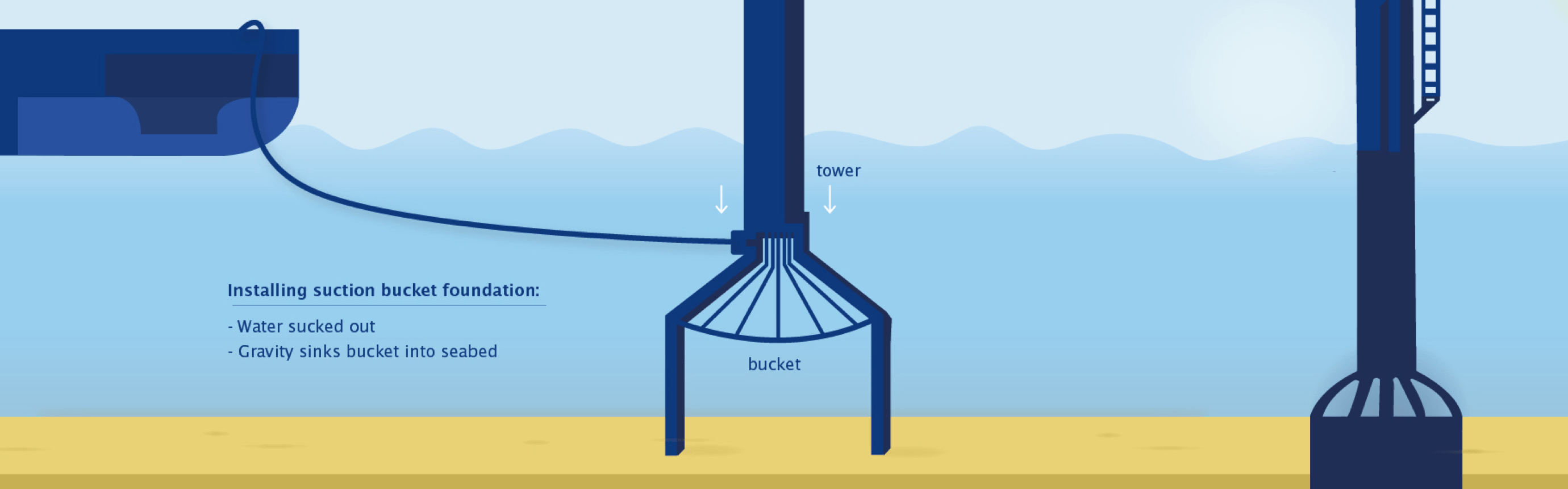

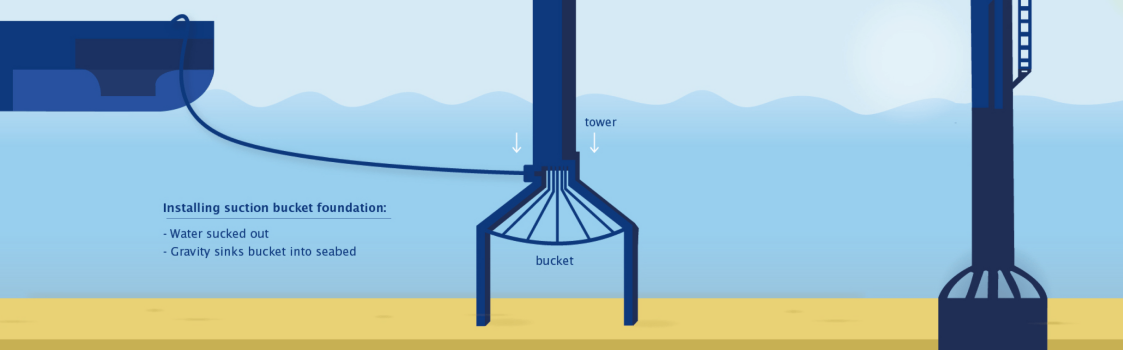

Keeping our eyes and ears open

The methods used to install offshore wind turbine foundations will undoubtedly change over time. We are keeping a close eye on developments and investing in innovations. The suction bucket is a good example. Installation methods are becoming increasingly ingenious and sustainable. And they must, of course, be cost-effective.

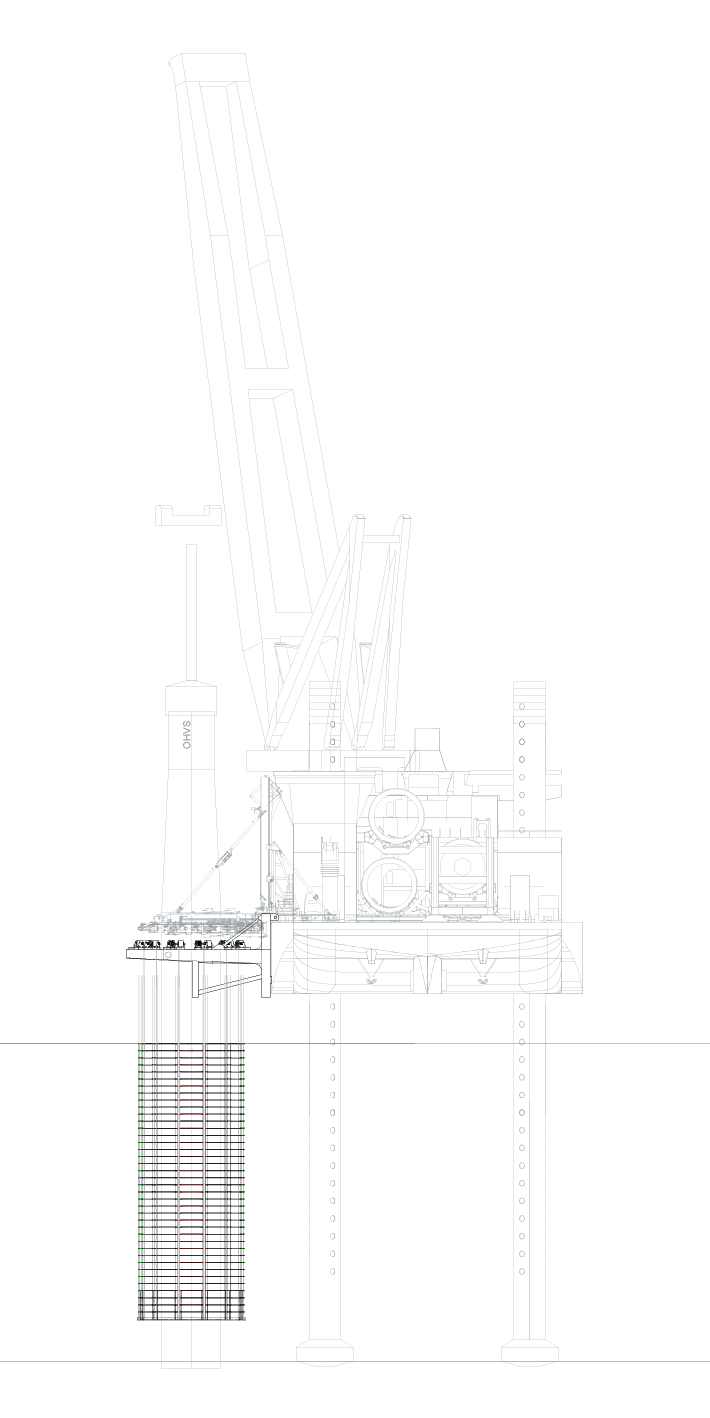

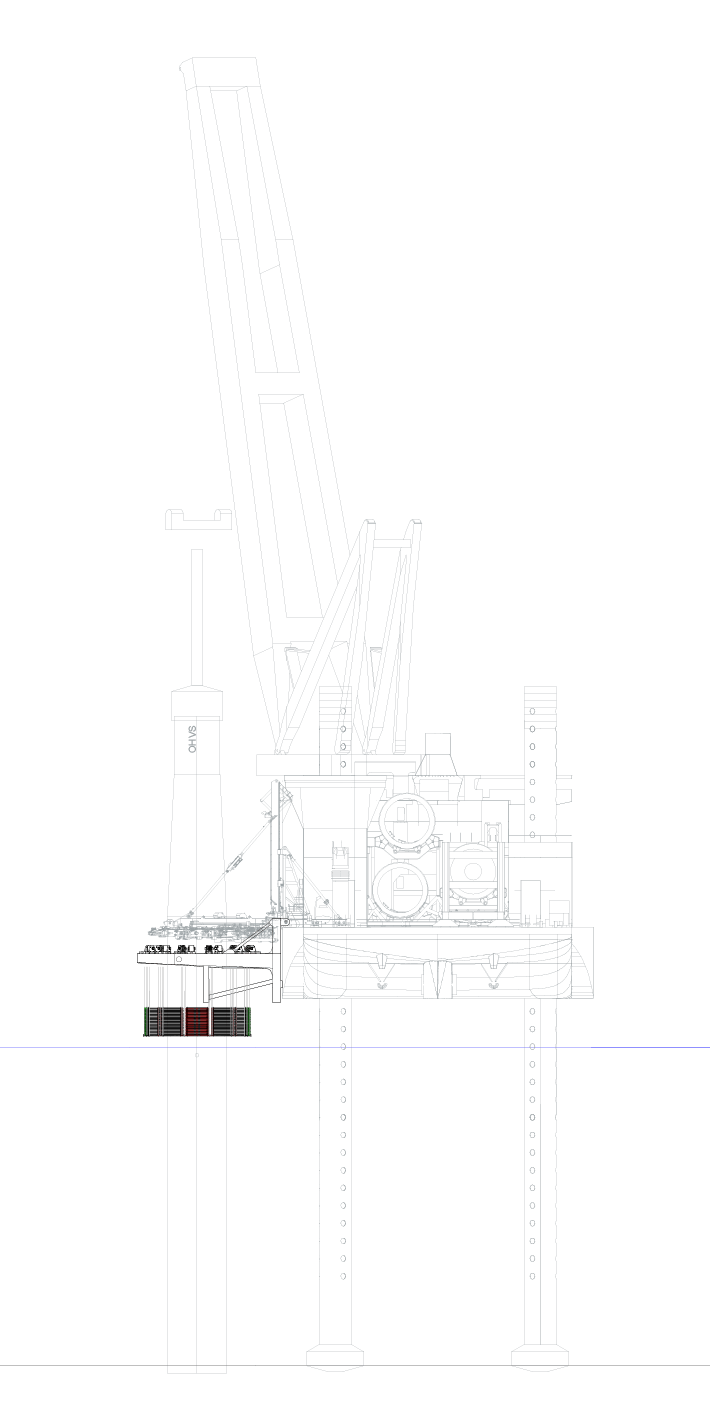

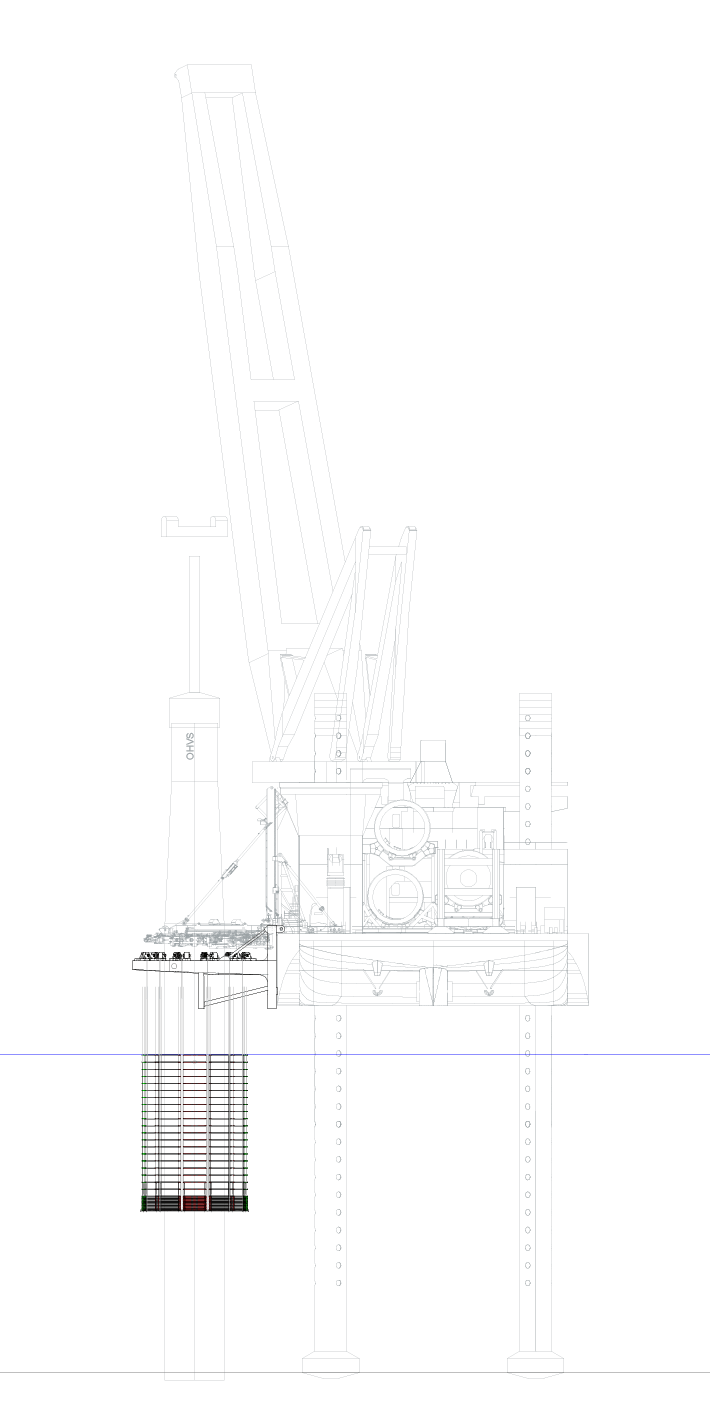

How it works in five steps

The NMS is folded up and transported to the construction site on the installation vessel.

Once we arrive at the construction site, we suspend the NMS from the side of the vessel.

We then place the gripper above the NMS and install the monopile in the gripper.

The system is then unfolded. It surrounds the monopile from the surface of the water right down to the seabed.

Pile driving can then begin.

Lianke te Raa & Frank

van den Berg

Bob Meijer

The NMS makes it possible to work through the winter

When offshore pile driving exceeds noise standards, you have to bring the work to a halt. It’s that simple. In the Netherlands, the standard for underwater noise varies with the time of year, among other things. We will start installing the first monopiles at the Borssele III, IV and V sites in October. The calculations show that a big bubble curtain alone will be sufficient as a noise reduction measure at that point. But the requirements in winter are stricter and that means that we’ll need the NMS on our project from January 2020. That’s why we are delighted that the system is now operational. Otherwise, we would have had to find an alternative.’

The NMS in practical terms

Every noise mitigation system is unique. One advantage of the NMS is that it is fitted to the vessel that installs the wind turbine foundations.

Jan Willem Elleswijk

In the Netherlands, the standard for underwater noise varies with the time of year, among other things.

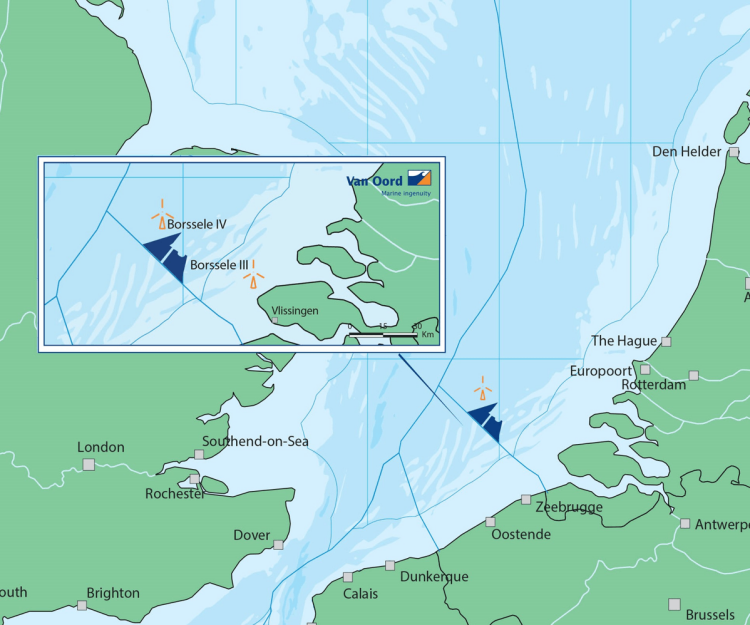

The trials showed that combining the NMS with a big bubble curtain satisfies the Dutch standards for noise emissions at sea. That is why Van Oord is using the system on the Borssele wind farm project at sites III, IV and V. Project Director Jan Willem Elleswijk explains this choice.

Van Oord

Jan Willem Elleswijk

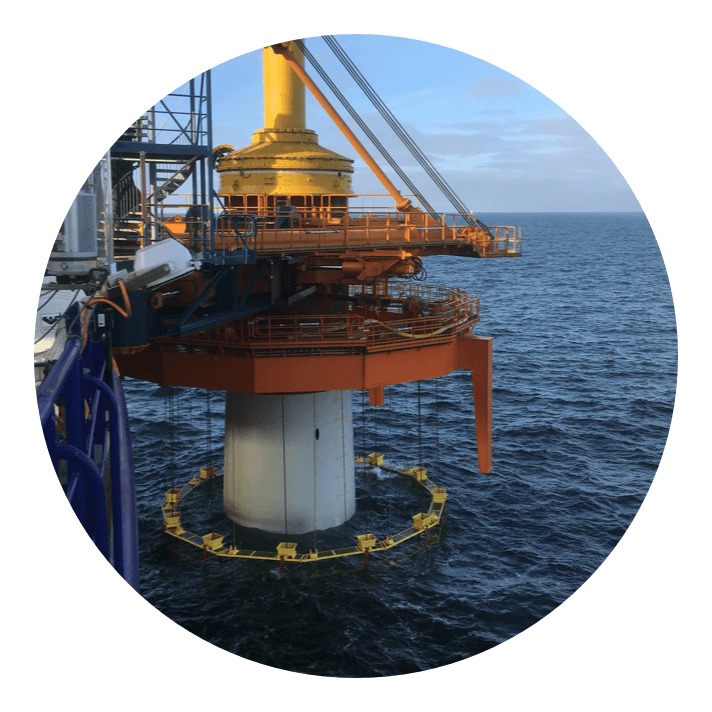

About the NMS

The innovative NMS absorbs underwater noise from offshore pile driving. It uses special Helmholtz acoustic resonators made by AdBm Technologies that attenuate the noise frequencies most harmful to marine mammals in the vicinity of the construction site.

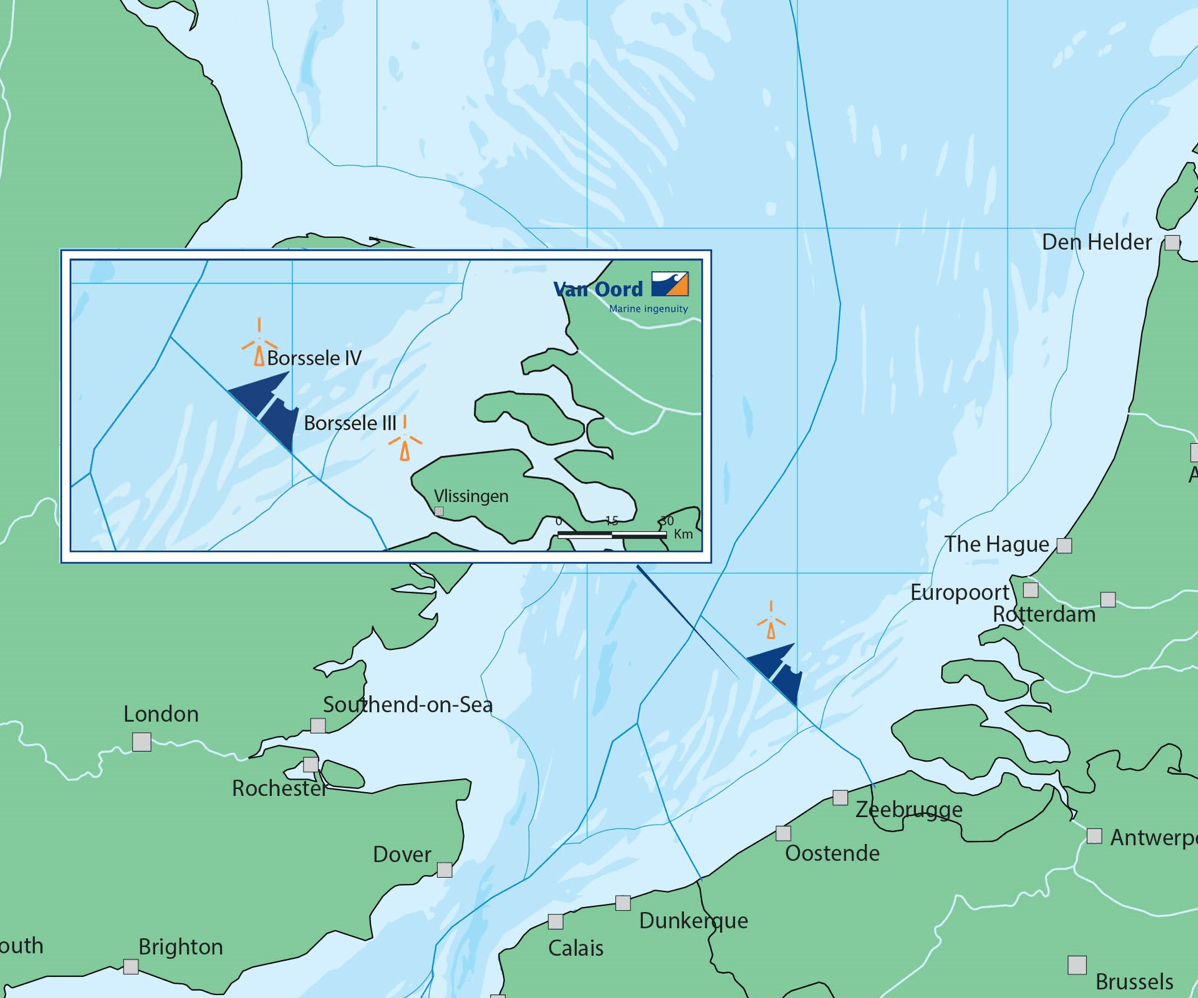

Borssele III, IV and V

After successful trials in which the NMS was tested extensively in the North Sea, Van Oord will begin using the system in 2020 on sites III, IV and V of the Borssele wind farm.

More peace and quiet for marine mammals during the construction of offshore wind farms

Jan Willem Elleswijk

Van Oord

Lianke te Raa &

Frank van den Berg

TNO

Bob Meijer

TKI Wind op Zee

Experts point of view

Our society needs offshore wind projects to meet its renewable energy targets. Unfortunately, the noise that such construction projects generate below the water surface can have an impact on marine life. That’s why we invest in the AdBm Noise Mitigation System.

Quieter pile driving

Sustainability

Bob Meijer

Our aim is to help make the energy transition possible and to accelerate it, and it was from that perspective that we recognised the potential of the NMS.

Trials needed for successful roll-out of innovations

The added value of an innovation becomes clear when it’s effectively applied in a series of trials. Such trials show whether the system does what it’s supposed to do, what it means to use the system on an actual project, and what it costs. All this information is essential for the successful roll-out of the innovation. As a result, the trials represent an important milestone in the ongoing development of innovations.

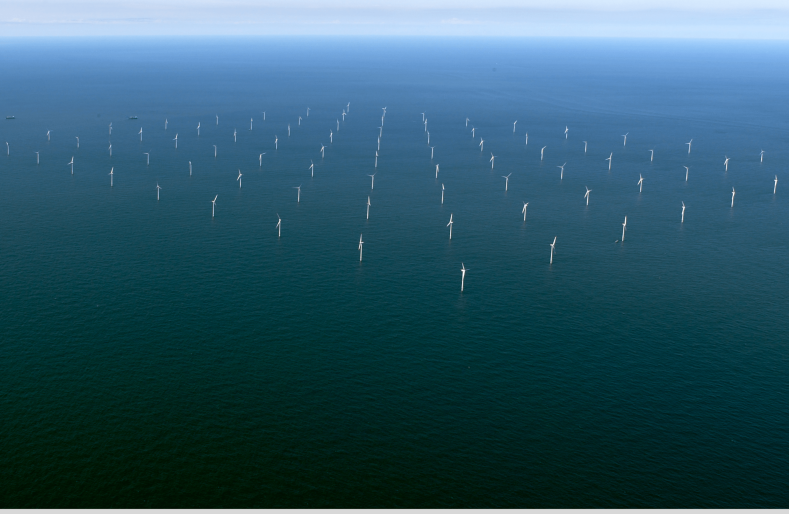

Multiple use of space

The Netherlands Environmental Assessment Agency has calculated that the North Sea can accommodate about 12,000 wind turbines each with a capacity of 5 MW. Building wind farms in the North Sea that will deliver 60 GW of power requires clever use of space. We’re working on these sorts of topics as well. For example, a wind farm can do double duty as an incubator for marine wildlife. That way we facilitate the energy transition and we support biodiversity in the North Sea.

NMS made possible thanks to the assistance of TKI Wind op Zee

For a long time it was unclear whether underwater noise affected marine life and, if so, to what extent. Much research has been done in recent years to find answers to these important questions. We facilitate such research and encourage innovations that reduce the impact of underwater noise. Our aim is to help make the energy transition possible and to accelerate it, and it was from that perspective that we recognised the potential of the NMS. That is in part why we subsidised its development and the associated trials.

The NMS and similar innovations are crucial to the energy transition

The Climate Agreement focuses on lowering carbon emissions by 95% in 2050 compared to 1990 levels. Our government is therefore committed to expanding offshore wind energy. But this raises other issues, for example the problem of underwater noise during construction. Installing wind turbine foundations in the North Sea almost always requires pile driving. Without precautionary measures this methodology impacts marine mammals. To protect them, there are strict rules for noise emissions at sea, based on the aforementioned research evidence. Violating the standards is not an option but noise mitigation systems and other smart solutions are.

The construction of offshore wind farms raises concerns about marine life, and the sector is subject to strict rules in that regard. That’s why noise mitigation systems are so important. TKI Wind op Zee supported the development of the NMS and the associated trials. Its director, Bob Meijer, shares his thoughts.

TKI Wind op Zee

Bob Meijer

From data to useful information

The German firm of consulting engineers ITAP registered the underwater noise during the trials. They did so based on a measurement plan that we developed. Their readings yielded loads of data. How do you turn data into useful information? We analysed and interpreted the outcomes and discussed any unexpected results with Van Oord and AdBm Technologies. The specialists involved were eager to share information about what they do, why they do it, and how. We complemented one another's knowledge and expertise perfectly.

Knowing what to expect

Because the NMS is new, we wanted to assess its estimated noise reduction capability. We did this by developing a specific model for it. The data delivered by such models is absolutely essential in the preparation phase of offshore wind projects. After all, you don't want to have to stop construction of a wind farm because you've exceeded the standards for underwater noise. You want to know what to expect so that you can plan ahead.

The specialists involved were eager to share information about what they do, why they do it, and how. We complemented one another's knowledge and expertise perfectly.

Lianke te Raa & Frank van den Berg

Condition of seabed important factor in NMS noise reduction

The trials showed that our model had given us a fairly accurate prediction of the NMS's noise reduction capability. We also learned that the NMS is most effective at sites where the seabed itself absorbs a lot of noise. We further saw that the results of our model depend heavily on the precise composition of the seabed at the construction site. What type of soil is it, how is it stratified, what is its absorption capacity? Such factors determine how sound is transmitted through the seabed, whether it reverberates to the water column and, if so, to what extent and where.

Nurturing industry with the power of innovation

We help companies such as Van Oord to make the right choices as they develop and apply measures to reduce underwater noise. Have you ever dived into the North Sea? If so, then you know that you can’t see a thing. That’s why marine animals there depend on their hearing to find food, to communicate with one another, to find mates, and so on. Human noise can disturb and possibly even damage marine wildlife, so we need to set and respect limits on underwater noise.

The independent research organisation TNO accumulates knowledge and advises authorities and businesses, including those in the offshore sector, on how to apply that knowledge in the field. Underwater noise specialists Lianke te Raa and Frank van den Berg were involved in the demonstration project of the NMS from the very beginning. They share their thoughts on their experience.

TNO

Lianke te Raa &

Frank van den Berg

Always room for improvement

We’re using all available knowledge to improve the NMS in cooperation with our partner AdBm Technologies. This Texas start-up develops and produces the NMS’s acoustic resonators, which are adjusted to absorb the most harmful underwater noise. One of our engineers visited AdBm’s experts in June to observe their testing of new system configurations. Each and every step delivers new knowledge and is therefore valuable. Together, we are optimising the system’s performance.

Keeping our eyes and ears open

The methods used to install offshore wind turbine foundations will undoubtedly change over time. We are keeping a close eye on developments and investing in innovations. The suction bucket is a good example. Installation methods are becoming increasingly ingenious and sustainable. And they must, of course, be cost-effective.

1

How it works in five steps

The NMS is folded up and transported to the construction site on the installation vessel.

Once we arrive at the construction site, we suspend the NMS from the side of the vessel.

We then place the gripper above the NMS and install the monopile in the gripper.

The system is then unfolded. It surrounds the monopile from the surface of the water right down to the seabed.

Pile driving can then begin.

Jan Willem Elleswijk

In the Netherlands, the standard for underwater noise varies with the time of year, among other things.

The NMS makes it possible to work through the winter

When offshore pile driving exceeds noise standards, you have to bring the work to a halt. It’s that simple. In the Netherlands, the standard for underwater noise varies with the time of year, among other things. We will start installing the first monopiles at the Borssele III, IV and V sites in October. The calculations show that a big bubble curtain alone will be sufficient as a noise reduction measure at that point. But the requirements in winter are stricter and that means that we’ll need the NMS on our project from January 2020. That’s why we are delighted that the system is now operational. Otherwise, we would have had to find an alternative.’

The NMS in practical terms

Every noise mitigation system is unique. One advantage of the NMS is that it is fitted to the vessel that installs the wind turbine foundations.

The trials showed that combining the NMS with a big bubble curtain satisfies the Dutch standards for noise emissions at sea. That is why Van Oord is using the system on the Borssele wind farm project at sites III, IV and V. Project Director Jan Willem Elleswijk explains this choice.

Van Oord

Jan Willem Elleswijk