A16: Green link for the Rotterdam region

Before the coronavirus outbreak, traffic jams were a daily occurrence on the A13 and A20 motorways near Rotterdam. To improve access to Rotterdam and quality of life in the region, Rijkswaterstaat and De Groene Boog consortium are constructing a new, 11-kilometre-long motorway.

The A16 Rotterdam motorway project received a Sustainable Pearl Award in January 2020.

Sustainable Pearl

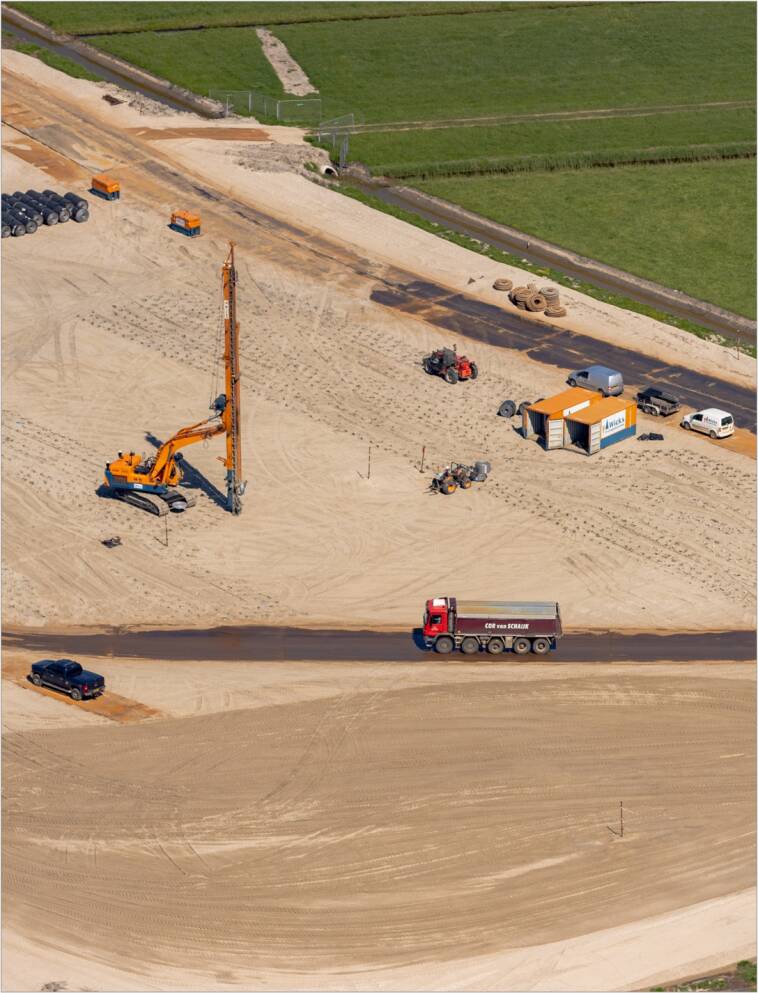

The supply chain starts at the source, Lake Markermeer. From there, the sand is shipped to 5 unloading sites. ‘Fortunately, we’d just started large-scale sand transport when the virus hit. At this phase of the project we’re mainly using heavy-duty equipment, so people aren’t working cheek by jowl and the work has been able to continue without any holdups.

We have a fleet of lorries waiting at the unloading sites to take the sand to the project site. Altogether, we’re looking at 200,000 trips. We’d agreed with local representatives to operate outside peak traffic hours and at set times to take pressure off the road. The pandemic meant that traffic is quieter than usual and delivery goes even better than planned. The downside is that local residents are at home a lot and there’s less background noise, so any unusual noises really stick out.

We’ll continue talking to the local community to explain what we’re doing. If they’re inconvenienced by our extra supply operations, we’ll do something about it. The whole team works like a well-oiled machine, with a supply chain that stretches from the water to the road. That makes me happy,’ Van der Voorn concludes.

meetings remotely. But we missed the informal chats because that’s when we often swap useful information. We got around this by setting up our own project App. We share photographs and information so that everyone’s up to speed. I’m stationed in the Province of Zeeland, for example, but thanks to the regular updates I know what’s happening on the project site.’

Lockdown-style communication

The coronavirus arrived in the Netherlands in early spring. Once the lockdown was announced, the A16 Rotterdam project team worked from home whenever possible. Van der Voorn explains that the team had all the necessary digital communication tools right from the start. ‘We had no trouble continuing our business

Stefan van der Voorn

Contract Manager

Rijkswaterstaat

Sand supply chain

Building a new motorway requires a lot of sand – a total of about 4 million cubic metres, in fact. That’s where Van Oord comes in.

‘More than 1,000 people will be working on the project at its peak. Accomplishing what we set out to do in only 6 years takes effective communication and close cooperation. That’s why Rijkswaterstaat and the De Groene Boog consortium operate as one team to manage the project, with everyone working in the same building.’ Speaking is Stefan van der Voorn, Rijkswaterstaat’s Contract Manager.

The motorway is already taking shape and we’re keeping close tabs on its progress. What will it take to finish this major project while the world is in the grip of a pandemic?

Sand

supply

chain

The A16 Rotterdam motorway project is massive and involves constructing a semi-immersed tunnel and adapting existing roads and junctions.

takes shape

motorway

The A16 Rotterdam motorway project is massive and involves constructing a semi-immersed tunnel and adapting existing roads and junctions.

A16 Rotterdam motorway project

New

6

1

A

Van Oord commissioned the first heavy-duty fully electric hydraulic excavator in the Netherlands this August. With this investment, Van Oord is demonstrating its pioneering role in the field of sustainability and responding to the desire of more and more clients to reduce emissions during project execution.

The award recognises projects that find unique ways to apply the Sustainable Infrastructure Approach. The project team won the award for its above-average commitment to sustainability. ‘We’ve dedicated ourselves to sustainability on this project,’ says Van der Voorn.

‘We’re building 11 kilometres of motorway, including a 2.2-kilometre-long tunnel that will be entirely energy-neutral. We’re also studying how to reduce carbon emissions during construction and what extra steps we can take on the project site, for example using electrically powered equipment and hydrotreated vegetable oil (HVO). We already have a number of lorries running on this renewable diesel fuel.’

The A16 Rotterdam motorway project received a Sustainable Pearl Award in January 2020.

Sustainable Pearl

The supply chain starts at the source, Lake Markermeer. From there, the sand is shipped to 5 unloading sites. ‘Fortunately, we’d just started large-scale sand transport when the virus hit. At this phase of the project we’re mainly using heavy-duty equipment, so people aren’t working cheek by jowl and the work has been able to continue without any holdups.

We have a fleet of lorries waiting at the unloading sites to take the sand to the project site. Altogether, we’re looking at 200,000 trips. We’d agreed with local representatives to operate outside peak traffic hours and at set times to take pressure off the road. The pandemic meant that traffic is quieter than usual and delivery goes even better than planned. The downside is that local residents are at home a lot and there’s less background noise, so any unusual noises really stick out.

We’ll continue talking to the local community to explain what we’re doing. If they’re inconvenienced by our extra supply operations, we’ll do something about it. The whole team works like a well-oiled machine, with a supply chain that stretches from the water to the road. That makes me happy,’ Van der Voorn concludes.

Building a new motorway requires a lot of sand – a total of about 4 million cubic metres, in fact. That’s where Van Oord comes in.

Sand supply chain

Lockdown-style communication

The coronavirus arrived in the Netherlands in early spring. Once the lockdown was announced, the A16 Rotterdam project team worked from home whenever possible. Van der Voorn explains that the team had all the necessary digital communication tools right from the start. ‘We had no trouble continuing our business meetings remotely. But we missed the informal chats because that’s when we often swap useful information. We got around this by setting up our own project App. We share photographs and information so that everyone’s up to speed. I’m stationed in the Province of Zeeland, for example, but thanks to the regular updates I know what’s happening on the project site.’

Stefan van der Voorn

Contract Manager

Rijkswaterstaat

‘More than 1,000 people will be working on the project at its peak. Accomplishing what we set out to do in only 6 years takes effective communication and close cooperation. That’s why Rijkswaterstaat and the De Groene Boog consortium operate as one team to manage the project, with everyone working in the same building.’ Speaking is Stefan van der Voorn, Rijkswaterstaat’s Contract Manager.

Innovations have made the A16 Rotterdam project unique. Once this new stretch of motorway is in use, solar panels will generate all the energy needed to operate the roadside and tunnel lighting and other systems. Van Oord and its partners in De Groene Boog consortium are executing the project for Rijkswaterstaat, the Netherlands’ public works agency. De Groene Boog consists of BESIX, Dura Vermeer, John Laing, Rebel, Van Oord and TBI subsidiaries Croonwolter&Dros and Mobilis.

Before the coronavirus outbreak, traffic jams were a daily occurrence on the A13 and A20 motorways near Rotterdam. To improve access to Rotterdam and quality of life in the region, Rijkswaterstaat and De Groene Boog consortium are constructing a new, 11-kilometre-long motorway.

A16: Green link for the Rotterdam region

The motorway is already taking shape and we’re keeping close tabs on its progress. What will it take to finish this major project while the world is in the grip of a pandemic?

takes shape

motorway

A16 Rotterdam motorway project

New

The A16 Rotterdam motorway project is massive and involves constructing a semi-immersed tunnel and adapting existing roads and junctions.

6

1

A