Drilling in hard seabed 2.0

Aeolus gets to work

Tough conditions on the French coast

‘This is the first time ever that vertical drilling will be carried out in such hard rock at these depths and on this scale.’

Rosemarijn Dekker

Rosemarijn Dekker, Engineering Manager Van Oord Offshore Wind, explains all about the Saint-Brieuc Offshore Wind Farm project in France.

as it's meant to be

Marine

ingenuity

Marine ingenuity as it’s meant to be

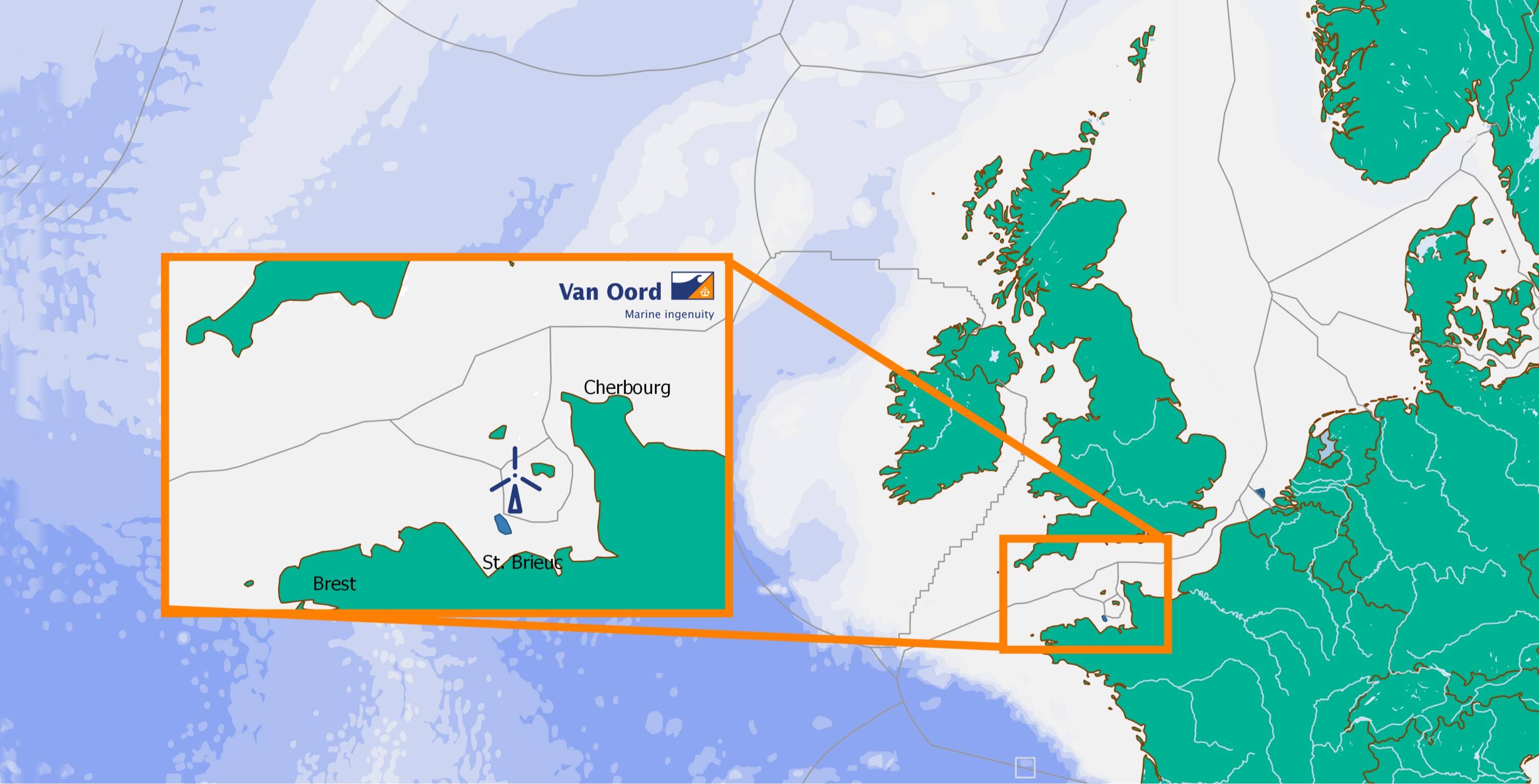

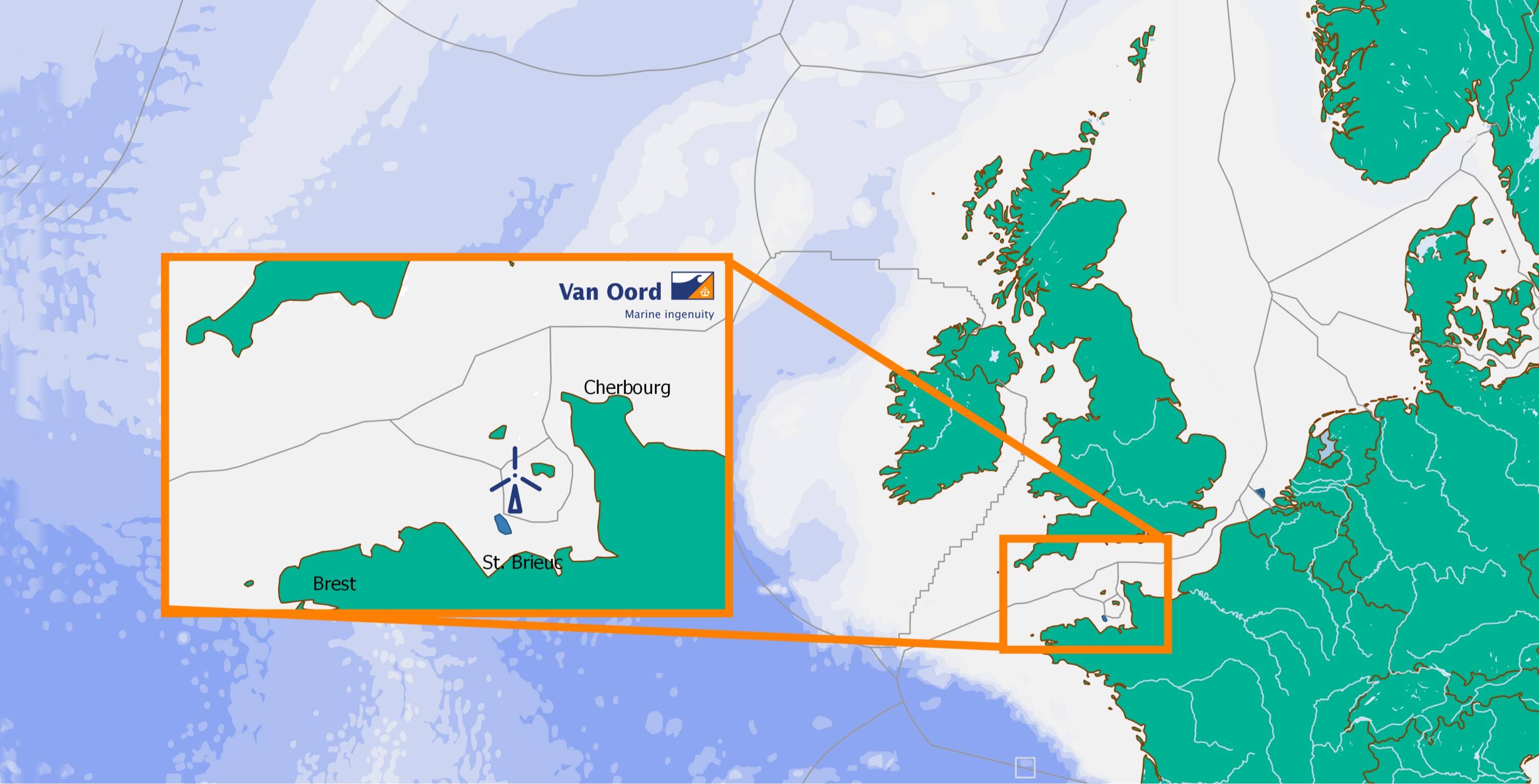

'It is fair to say that the conditions for building a wind farm along the coast of Saint-Brieuc are challenging,’ says Rosemarijn Dekker. Rosemarijn knows what she’s talking about: she’s been involved in the Saint-Brieuc offshore wind farm as Engineering Manager since 2018. Van Oord will start installing the jacket foundations for the wind farm, a project commissioned by Ailes Marines SAS (wholly-owned subsidiary of Iberdrola), in 2021. Once on stream in 2023, the wind farm will generate enough clean energy for 835,000 people.

'The seabed is uneven and littered with rock and gigantic boulders. In short, conditions for positioning and jacking up a vessel are pretty tricky. We need to drill in a very hard seabed, with rock strengths exceeding 100 MPa, at all the turbine locations. Ultimately, we’ll need to drill through about 4 kilometres of rock.’

On top of the tough drilling conditions, the weather and tide also play a key role. ‘There’s a tidal range of 12 metres, extremely strong currents, heavy Atlantic swell and very high waves,’ says Rosemarijn. ‘The harsh weather conditions mean that offshore operations are only possible between March and October. All in all, these are unprecedented circumstances for us.’

62 jacket foundations

'You hit rock as soon as you’re out to sea. Even so, France wants to generate sustainable energy, and offshore wind farms are part of its strategy,’ Rosemarijn explains. ‘For the Saint-Brieuc wind farm we’re installing a total of 62 jacket foundations as well as the foundation piles for the offshore substation. We’re using 190 pin piles and the site is about 75 square kilometres.'

‘A lot of the ‘easy’ offshore wind farm sites in Western Europe have been taken. What’s left are the more difficult locations. In fact, there aren’t many easy sites along the French coast at all.'

Tough conditions on the French coast

Tough conditions on the French coast

Drilling in hard seabed 2.0

Marine ingenuity as it’s meant to be

'We knew that our client was charmed by the idea of using a jack-up vessel because once it’s standing, the waves aren’t such a problem. We might spend up to 5 days drilling at difficult locations and the vessel has to remain at the same spot all that time.’

‘We pulled out all the stops to ensure that we could deploy the Aeolus safely,’ says Rosemarijn. ‘We brought in colleagues from different disciplines. For example, our hydrodynamics team simulated the influence of waves and swell on the vessel’s operational capacity.

But we also asked the Aeolus’s crew for their input. Our Dredging business unit advised us on heavy-duty cutters and we learned a lot from constructing the East Anglia One offshore wind farm. This is Marine ingenuity as it’s meant to be.’

‘Our tender was based on the premise that we’d be using offshore installation vessel Aeolus,’ explains Rosemarijn. ‘But that means we’d have to be able to jack up the vessel, and that’s a challenge on this hard seabed combined with these waves.'

Aeolus gets to work

Aeolus gets to work

‘The tender process for such a unique and challenging project can only be successful when everyone works as a single team. And we found that Van Oord has an open culture, as well as many specialists and a lot of experience. The COVID-19 pandemic has been an extra challenge, since working in virtual rooms is quite different from working in the same physical room. It takes a lot more time, but we’ve managed it smoothly thanks to close cooperation between Van Oord and BAUER.’

Frank Haehnig

Managing Director BAUER

‘The Dive Drill can handle all kinds of soil and rock conditions to allow installation of any kind of pile in the seabed. The need to use sustainable drilling equipment in challenging soil conditions and a harsh environment drove our decision to develop the Dive Drill. Using components from our existing equipment portfolio and combining them with new and innovative ideas has produced a solution that satisfies the project requirements.’

Frank Haehnig

Managing Director BAUER

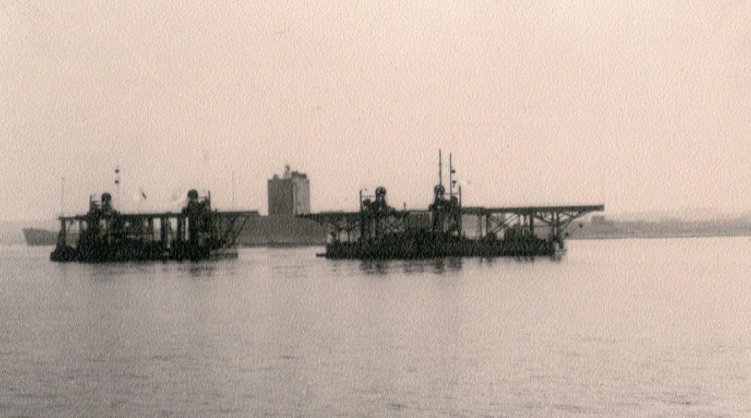

History repeats itself

Rocky soil conditions and the development of French ports: Van Oord has an outstanding reputation in both areas. To boost their economy after the Second World War, the French developed an industrial gateway to Europe known as Europort Sud.

Sometimes a picture is worth a thousand words. One of Iberdrola’s main requirements was that we had to deliver a robust solution. But what’s the best way to explain a technically complex method? An animation does the trick

‘During the tender phase, we discovered that there aren’t many companies that can achieve the speed we’re looking for,’ says Rosemarijn. The BAUER Group was selected as the preferred contractor and they developed the Dive Drill, a drill that operates entirely below the surface of the water.

The

technique

explained

Marine ingenuity as it’s meant to be

‘During the tender phase, we discovered that there aren’t many companies that can achieve the speed we’re looking for,’ says Rosemarijn. The BAUER Group was selected as the preferred contractor and they developed the Dive Drill, a drill that operates entirely below the surface of the water.

Rosemarijn explains: ‘The drill is hydraulically powered. It’s lowered down through a temporary casing. Once it’s drilled down to the right depth, the drill is removed and the pin pile is inserted. The oscillator slowly raises the casing to the surface again while grout is being injected into the opening.’

With the Dive Drill in place, the Aeolus can do what it has proven to be incredibly good at: installing the foundations for this wind farm.

When offshore wind farm construction calls for subsea drilling in hard seabed, Van Oord joins forces with the BAUER Group.

Drilling in hard seabed 2.0

Drilling in hard seabed 2.0

Aeolus gets to work

Tough conditions on the French coast

'This is the first time ever that vertical drilling will be carried out in such hard rock at these depths and on this scale.'

Rosemarijn Dekker

Rosemarijn Dekker, Engineering Manager Van Oord Offshore Wind, explains all about the Saint-Brieuc Offshore Wind Farm project in France.

as it's meant to be

Marine

ingenuity

'It is fair to say that the conditions for building a wind farm along the coast of Saint-Brieuc are challenging,’ says Rosemarijn Dekker. Rosemarijn knows what she’s talking about: she’s been involved in the Saint-Brieuc offshore wind farm as Engineering Manager since 2018. Van Oord will start installing the jacket foundations for the wind farm, a project commissioned by Ailes Marines SAS (wholly-owned subsidiary of Iberdrola), in 2021. Once on stream in 2023, the wind farm will generate enough clean energy for 835,000 people.

'The seabed is uneven and littered with rock and gigantic boulders. In short, conditions for positioning and jacking up a vessel are pretty tricky. We need to drill in a very hard seabed, with rock strengths exceeding 100 MPa, at all the turbine locations. Ultimately, we’ll need to drill through about 4 kilometres of rock.’

On top of the tough drilling conditions, the weather and tide also play a key role. ‘There’s a tidal range of 12 metres, extremely strong currents, heavy Atlantic swell and very high waves,’ says Rosemarijn. ‘The harsh weather conditions mean that offshore operations are only possible between March and October. All in all, these are unprecedented circumstances for us.’

62 jacket foundations

'You hit rock as soon as you’re out to sea. Even so, France wants to generate sustainable energy, and offshore wind farms are part of its strategy,’ Rosemarijn explains. ‘For the Saint-Brieuc wind farm we’re installing a total of 62 jacket foundations as well as the foundation piles for the offshore substation. We’re using 190 pin piles and the site is about 75 square kilometres.'

‘A lot of the ‘easy’ offshore wind farm sites in Western Europe have been taken. What’s left are the more difficult locations. In fact, there aren’t many easy sites along the French coast at all.'

Tough conditions on the French coast

Marine ingenuity as it’s meant to be

‘We pulled out all the stops to ensure that we could deploy the Aeolus safely,’ says Rosemarijn. ‘We brought in colleagues from different disciplines. For example, our hydrodynamics team simulated the influence of waves and swell on the vessel’s operational capacity.

But we also asked the Aeolus’s crew for their input. Our Dredging business unit advised us on heavy-duty cutters and we learned a lot from constructing the East Anglia One offshore wind farm. This is Marine ingenuity as it’s meant to be.’

'We knew that our client was charmed by the idea of using a jack-up vessel because once it’s standing, the waves aren’t such a problem. We might spend up to 5 days drilling at difficult locations and the vessel has to remain at the same spot all that time.’

‘Our tender was based on the premise that we’d be using offshore installation vessel Aeolus,’ explains Rosemarijn. ‘But that means we’d have to be able to jack up the vessel, and that’s a challenge on this hard seabed combined with these waves.'

Aeolus gets to work

Marine ingenuity as it’s meant to be

‘The tender process for such a unique and challenging project can only be successful when everyone works as a single team. And we found that Van Oord has an open culture, as well as many specialists and a lot of experience. The COVID-19 pandemic has been an extra challenge, since working in virtual rooms is quite different from working in the same physical room. It takes a lot more time, but we’ve managed it smoothly thanks to close cooperation between Van Oord and BAUER.’

Frank Haehnig

Managing Director BAUER

To boost their economy after the Second World War, the French developed an industrial gateway to Europe known as Europort Sud. The removal of a rock at the entrance to Port de Bouc marked the start of a number of iconic French marine engineering projects between 1947 and 1983.

Boulder breaker HAM 906, developed in-house, proved to be a fine example of early Marine ingenuity. Between 1948 and 1964, 500,000 cubic metres of rock were removed from the Gulf of Fos. A fleet of dredgers removed 100 million cubic metres from the access channel in 1966, thus contradicting an official report stating it could not be done. In 1970, some 5 million cubic metres of dredged sand and gravel were used to expand the territory of the Principality of Monaco.

Like Van Oord, the BAUER Group is a company with a strong family tradition. The BAUER Group was founded in 1790 and is based in Schrobenhausen, Bavaria. Both Bauer and Van Oord are committed to developing safe, innovative and sustainable solutions in cooperation with their clients.

Rocky soil conditions and the development of French ports: Van Oord has an outstanding reputation in both areas.

History repeats itself

Rosemarijn explains: ‘The drill is hydraulically powered. It’s lowered down through a temporary casing. Once it’s drilled down to the right depth, the drill is removed and the pin pile is inserted. The oscillator slowly raises the casing to the surface again while grout is being injected into the opening.’

With the Dive Drill in place, the Aeolus can do what it has proven to be incredibly good at: installing the foundations for this wind farm.

‘The Dive Drill can handle all kinds of soil and rock conditions to allow installation of any kind of pile in the seabed. The need to use sustainable drilling equipment in challenging soil conditions and a harsh environment drove our decision to develop the Dive Drill. Using components from our existing equipment portfolio and combining them with new and innovative ideas has produced a solution that satisfies the project requirements.’

Frank Haehnig

Managing Director BAUER

Sometimes a picture is worth a thousand words. One of Iberdrola’s main requirements was that we had to deliver a robust solution. But what’s the best way to explain a technically complex method? An animation does the trick

‘During the tender phase, we discovered that there aren’t many companies that can achieve the speed we’re looking for,’ says Rosemarijn. The BAUER Group was selected as the preferred contractor and they developed the Dive Drill, a drill that operates entirely below the surface of the water.

When offshore wind farm construction calls for subsea drilling in hard seabed, Van Oord joins forces with the BAUER Group.

Drilling in hard seabed 2.0

Marine ingenuity as it’s meant to be