Read

the

article

Maurits den Broeder

Managing Director

Van Oord Offshore

Extreme precision

Van Oord’s task was to prevent the spread of mercury into the environment. Under the NCA’s requirements, the project team could permit no more than 220 millilitres – a single glassful – of mercury to spread outside the project area. Extreme precision was of vital importance, and measuring and monitoring were essential components of the project execution. A monitoring vessel used environmental and geotechnical measuring equipment installed in and around the project site to monitor vibrations and any movement of the bow.

Project facts & figures

Specially designed diffuser

Van Oord first installed a layer of sand to reduce erosion and dispersal. To ensure precision at a depth of 160 metres, Van Oord developed a fit-for-purpose diffuser that was then attached to flexible fallpipe vessel Stornes’ remotely operated vehicle (ROV). The vessel installed 30,000 tonnes of sand and then covered this half-metre-thick layer with 160,000 tonnes of rock. This ingenious solution, our thorough risk inventory and our ability to meet the strict environmental criteria convinced the client to partner with Van Oord on this project.

‘We awarded the contract to Van Oord because of their overall quality and risk-based approach. The NCA is very satisfied with the professionalism displayed by all employees.’

Hans Petter Mortensholm

Project Manager Norwegian Coastal Administration (NCA)

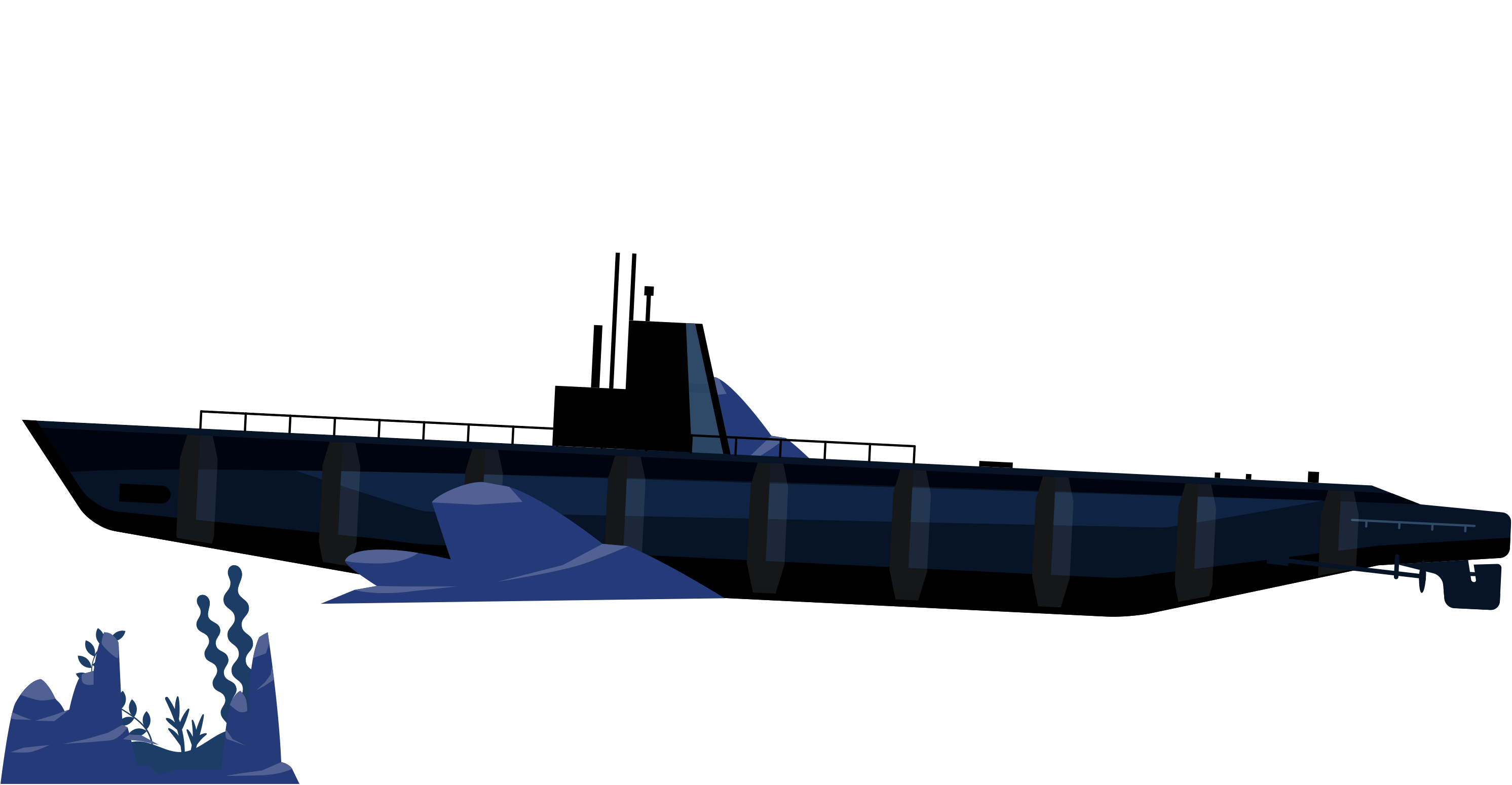

submarine wreck

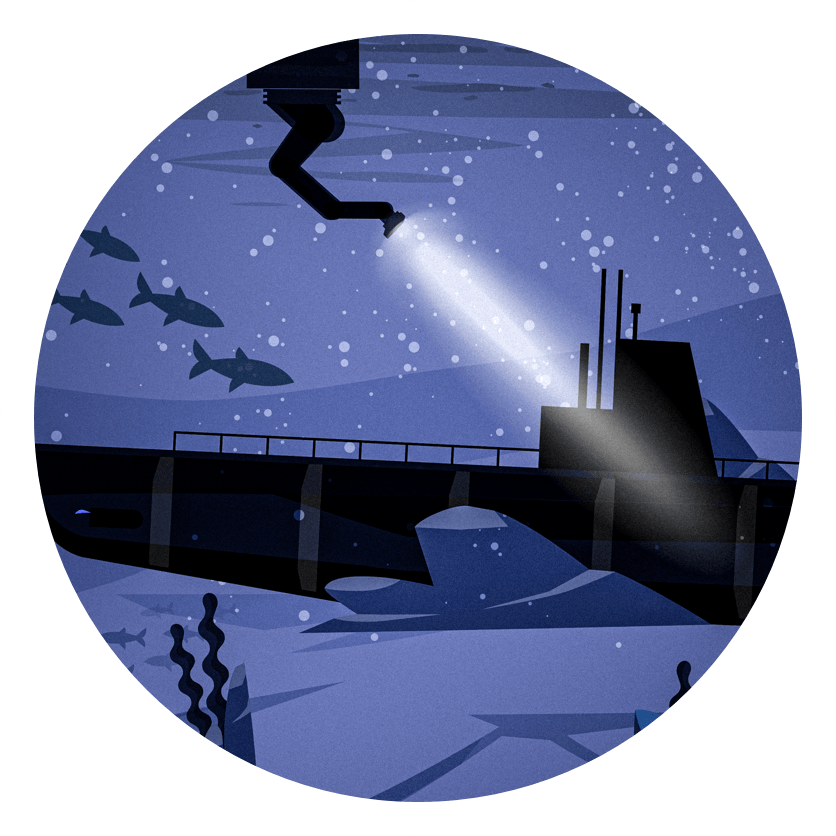

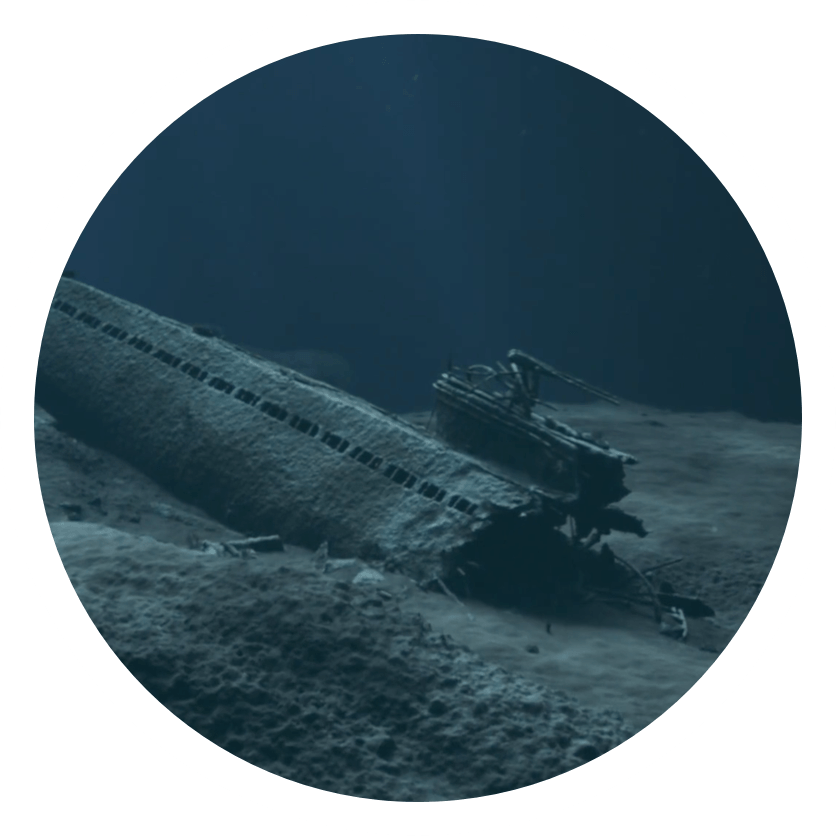

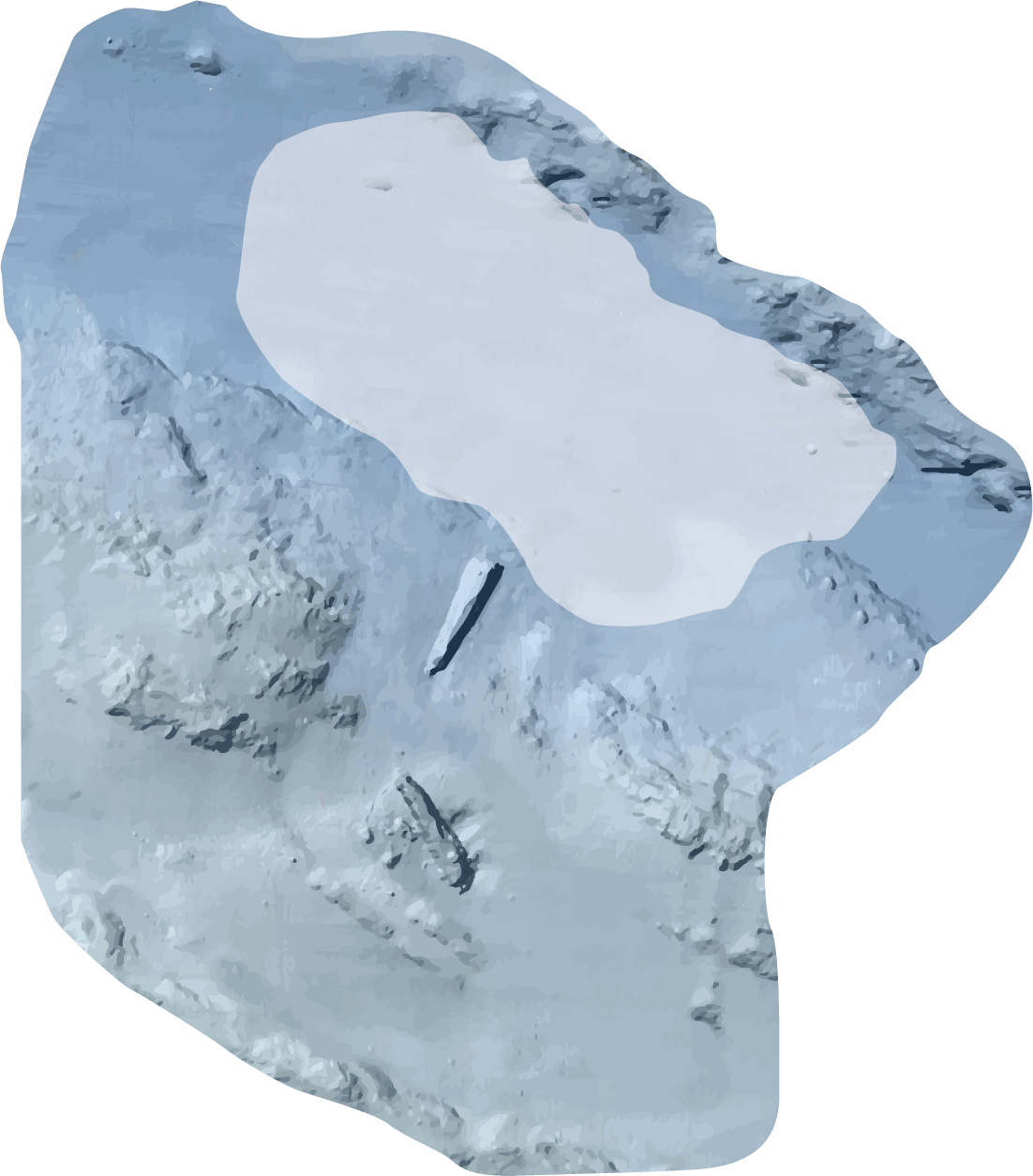

Almost 60 years after it was sunk during the Second World War, the wreck of the U-864, a German submarine, was found off the west coast of Norway. Its final journey was on 9 February 1945, when a British submarine fired on it, splitting it in half and sending it to the bottom of the sea.

World War II

Finished project

Stabilising a

Watch the project video

Toxic cargo

The wreck was discovered by Norway’s Royal Navy near the island of Fedje at 160 metres below sea level. What turned it into a nightmare for the Norwegian Coastal Administration (NCA) was its toxic cargo: 67 tonnes of liquid mercury. It seems that the German sub had been on a secret mission to ally Japan, codenamed ‘Caesar’. It was carrying liquid mercury meant for the munitions industry. The submarine never reached its destination and by the time it was discovered on the seabed, the toxic metal had already spread over an area of 30,000 square metres.

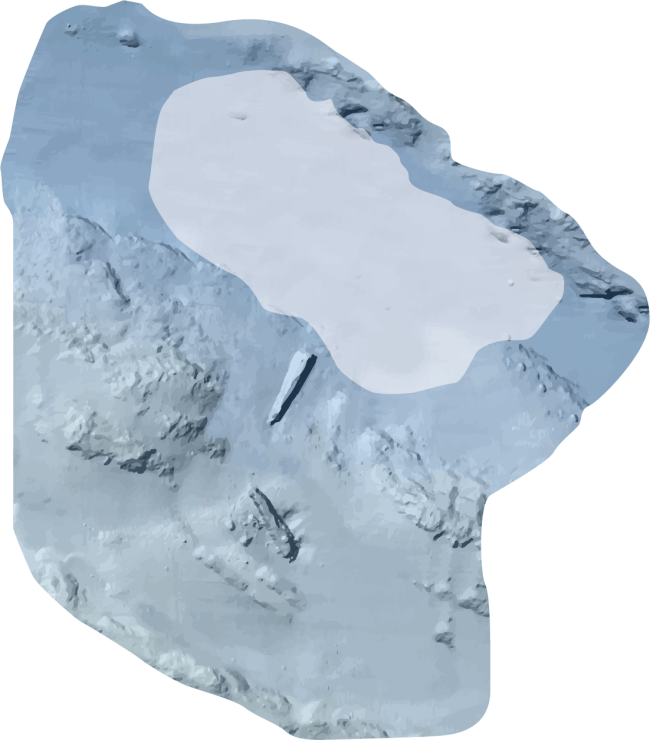

Stabilising the wreck

Preventing the mercury from spreading further would be no easy task for the NCA. The bow of the wreck had ended up at the edge of a slope. There was a risk that both the bow and the contaminated sediment around it would slide downwards. To prevent this, the NCA called in Van Oord to counter fill the contaminated seabed and to stabilise the wreck. Counter filling is a routine job for Van Oord, but the strict environmental criteria required by the presence of the wreck and the mercury made this project unique.

Read

the

article

‘We awarded the contract to Van Oord because of their overall quality and risk-based approach. The NCA is very satisfied with the professionalism displayed by all employees.’

Hans Petter Mortensholm

Project Manager Norwegian Coastal Administration (NCA)

Specially designed diffuser

Van Oord first installed a layer of sand to reduce erosion and dispersal. To ensure precision at a depth of 160 metres, Van Oord developed a fit-for-purpose diffuser that was then attached to flexible fallpipe vessel Stornes’ remotely operated vehicle (ROV). The vessel installed 30,000 tonnes of sand and then covered this half-metre-thick layer with 160,000 tonnes of rock. This ingenious solution, our thorough risk inventory and our ability to meet the strict environmental criteria convinced the client to partner with Van Oord on this project.

2 nautical miles west of Fedje Island

30,000 tonnes of sand installed

160,000 tonnes of rock installed

160 metres depth

Project facts & figures

Extreme precision

Van Oord’s task was to prevent the spread of mercury into the environment. Under the NCA’s requirements, the project team could permit no more than 220 millilitres – a single glassful – of mercury to spread outside the project area. Extreme precision was of vital importance, and measuring and monitoring were essential components of the project execution. A monitoring vessel used environmental and geotechnical measuring equipment installed in and around the project site to monitor vibrations and any movement of the bow.

Stabilising the wreck

Preventing the mercury from spreading further would be no easy task for the NCA. The bow of the wreck had ended up at the edge of a slope. There was a risk that both the bow and the contaminated sediment around it would slide downwards. To prevent this, the NCA called in Van Oord to counter fill the contaminated seabed and to stabilise the wreck. Counter filling is a routine job for Van Oord, but the strict environmental criteria required by the presence of the wreck and the mercury made this project unique.

‘Van Oord is determined to play an active role in caring for the planet by guarding the environment. This project is a great example of how we use our Marine ingenuity to do so.’

Maurits den Broeder

Managing Director

Van Oord Offshore

Toxic cargo

The wreck was discovered by Norway’s Royal Navy near the island of Fedje at 160 metres below sea level. What turned it into a nightmare for the Norwegian Coastal Administration (NCA) was its toxic cargo: 67 tonnes of liquid mercury. It seems that the German sub had been on a secret mission to ally Japan, codenamed ‘Caesar’. It was carrying liquid mercury meant for the munitions industry. The submarine never reached its destination and by the time it was discovered on the seabed, the toxic metal had already spread over an area of 30,000 square metres.

submarine wreck

Almost 60 years after it was sunk during the Second World War, the wreck of the U-864, a German submarine, was found off the west coast of Norway. Its final journey was on 9 February 1945, when a British submarine fired on it, splitting it in half and sending it to the bottom of the sea.

World War II

Finished project

Stabilising a